How do die casting molds ensure casting stability through high-precision machining?

Release Time : 2025-08-13

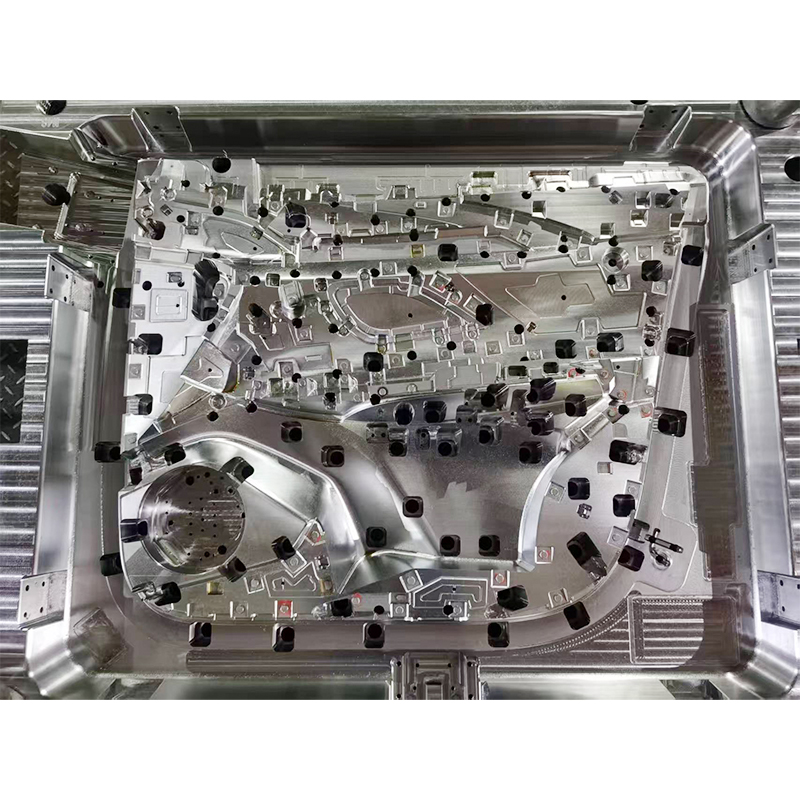

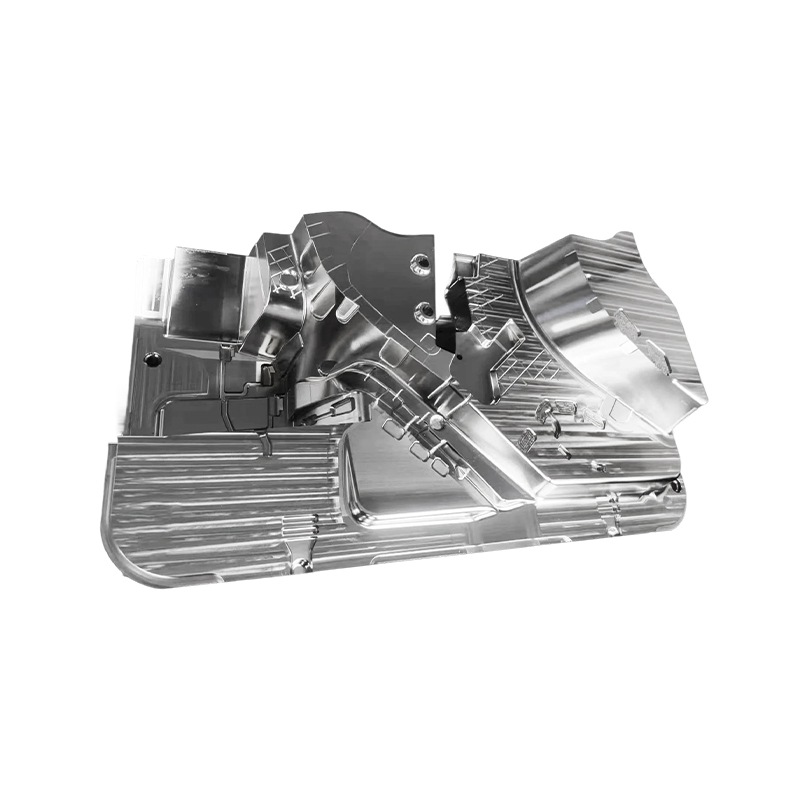

Die casting molds are critical tools for manufacturing high-quality metal parts. Their precision directly impacts the dimensional stability, surface quality, and mechanical properties of the final product. To meet increasingly stringent industry standards and customer requirements, modern die casting mold design and manufacturing processes increasingly prioritize the application of high-precision machining technologies.

1. The Importance of Material Selection

Material selection is crucial during the initial stages of die casting mold design. High-quality mold steel must not only possess high strength and hardness, but also excellent wear resistance and thermal fatigue resistance. Commonly used mold steels include H13 and P20, which maintain stable physical properties under high-temperature and high-pressure environments, ensuring long-term reliability and consistency. Furthermore, advanced heat treatment processes (such as quenching and tempering) can further enhance the overall performance of the mold steel, laying a solid foundation for subsequent high-precision machining.

2. Application of Precision Machining Equipment

To achieve high-precision machining, modern CNC machine tools and electrical discharge machining (EDM) equipment are widely used in die casting mold manufacturing. CNC machine tools are capable of cutting complex 3D contours, and their micron-level positioning and repeatability ensure consistent dimensions across all mold components. EDM, on the other hand, is particularly well-suited for machining complex shapes that are difficult to form using traditional cutting methods, such as deep cavities and small apertures. Combining these two technologies effectively reduces human error and improves overall mold precision.

3. Optimizing Mold Design and Simulation Analysis

During the mold design phase, engineers use computer-aided design (CAD) software to create detailed 3D models and simulate the casting process using mold flow analysis software. This virtual testing not only predicts potential problems (such as underfill and porosity formation) but also helps optimize the gating system, cooling channels, and vent layout. Proper mold design not only improves production efficiency but also significantly enhances the quality and stability of castings. For example, optimized runner design ensures uniform flow of molten metal into the mold cavity, preventing deformation caused by localized overheating or uneven cooling.

4. High-Precision Inspection Methods

After high-precision machining, the mold undergoes rigorous quality inspection using advanced measurement tools. Coordinate measuring machines (CMMs) are a commonly used and highly effective inspection tool. They can accurately measure the actual dimensions of key mold components, ensuring they conform to the design drawings. Furthermore, non-contact measuring instruments such as optical projectors and laser scanners are increasingly being used in mold inspection. They are not only fast and accurate, but also harmless to the mold surface. Analysis of inspection data allows for timely detection and correction of any deviations, ensuring the mold's dimensional stability and consistency.

5. The Role of Surface Treatment Technology

In addition to high-precision machining of internal structures, mold surface treatment is also crucial. Common surface treatment technologies include nitriding, carbonitriding, and PVD coating. These technologies create a hard, smooth protective film on the mold surface, enhancing its wear and corrosion resistance and extending its service life. Surface-treated molds also facilitate easier demolding, reducing product defects caused by adhesion. For specific applications, different surface treatment options can be selected based on actual needs to achieve optimal results.

6. Continuous Improvement and Feedback Mechanism

Finally, establishing an effective continuous improvement and feedback mechanism is crucial to ensuring the long-term stability and reliability of die casting molds. By collecting real-time data from the production line and customer feedback, companies can continuously optimize mold design and production processes. For example, common problems with specific casting models can be resolved by adjusting mold parameters or refining the processing technology. This continuous improvement model based on data analysis helps companies quickly respond to changing market demands and enhance their competitiveness.

In summary, die casting molds ensure the stability of castings through high-precision processing technology in multiple aspects. From material selection and the use of precision processing equipment to optimized mold design, rigorous quality inspection, and advanced surface treatment technology, every step is essential.

1. The Importance of Material Selection

Material selection is crucial during the initial stages of die casting mold design. High-quality mold steel must not only possess high strength and hardness, but also excellent wear resistance and thermal fatigue resistance. Commonly used mold steels include H13 and P20, which maintain stable physical properties under high-temperature and high-pressure environments, ensuring long-term reliability and consistency. Furthermore, advanced heat treatment processes (such as quenching and tempering) can further enhance the overall performance of the mold steel, laying a solid foundation for subsequent high-precision machining.

2. Application of Precision Machining Equipment

To achieve high-precision machining, modern CNC machine tools and electrical discharge machining (EDM) equipment are widely used in die casting mold manufacturing. CNC machine tools are capable of cutting complex 3D contours, and their micron-level positioning and repeatability ensure consistent dimensions across all mold components. EDM, on the other hand, is particularly well-suited for machining complex shapes that are difficult to form using traditional cutting methods, such as deep cavities and small apertures. Combining these two technologies effectively reduces human error and improves overall mold precision.

3. Optimizing Mold Design and Simulation Analysis

During the mold design phase, engineers use computer-aided design (CAD) software to create detailed 3D models and simulate the casting process using mold flow analysis software. This virtual testing not only predicts potential problems (such as underfill and porosity formation) but also helps optimize the gating system, cooling channels, and vent layout. Proper mold design not only improves production efficiency but also significantly enhances the quality and stability of castings. For example, optimized runner design ensures uniform flow of molten metal into the mold cavity, preventing deformation caused by localized overheating or uneven cooling.

4. High-Precision Inspection Methods

After high-precision machining, the mold undergoes rigorous quality inspection using advanced measurement tools. Coordinate measuring machines (CMMs) are a commonly used and highly effective inspection tool. They can accurately measure the actual dimensions of key mold components, ensuring they conform to the design drawings. Furthermore, non-contact measuring instruments such as optical projectors and laser scanners are increasingly being used in mold inspection. They are not only fast and accurate, but also harmless to the mold surface. Analysis of inspection data allows for timely detection and correction of any deviations, ensuring the mold's dimensional stability and consistency.

5. The Role of Surface Treatment Technology

In addition to high-precision machining of internal structures, mold surface treatment is also crucial. Common surface treatment technologies include nitriding, carbonitriding, and PVD coating. These technologies create a hard, smooth protective film on the mold surface, enhancing its wear and corrosion resistance and extending its service life. Surface-treated molds also facilitate easier demolding, reducing product defects caused by adhesion. For specific applications, different surface treatment options can be selected based on actual needs to achieve optimal results.

6. Continuous Improvement and Feedback Mechanism

Finally, establishing an effective continuous improvement and feedback mechanism is crucial to ensuring the long-term stability and reliability of die casting molds. By collecting real-time data from the production line and customer feedback, companies can continuously optimize mold design and production processes. For example, common problems with specific casting models can be resolved by adjusting mold parameters or refining the processing technology. This continuous improvement model based on data analysis helps companies quickly respond to changing market demands and enhance their competitiveness.

In summary, die casting molds ensure the stability of castings through high-precision processing technology in multiple aspects. From material selection and the use of precision processing equipment to optimized mold design, rigorous quality inspection, and advanced surface treatment technology, every step is essential.