In the era of new energy vehicles, how can front bumper mold processing achieve a breakthrough in lightweighting?

Release Time : 2025-08-27

As the new energy vehicle industry accelerates toward its "dual carbon" goals, lightweighting has become a core technological path to improving range and reducing energy consumption. As a key automotive exterior component, lightweighting the front bumper not only impacts overall vehicle weight reduction but also directly impacts crash safety performance and manufacturing costs. Faced with the stringent demands of new energy vehicles for "lighter, stronger, and more environmentally friendly" bumpers, the mold processing industry is embarking on a disruptive lightweighting breakthrough through material innovation, structural optimization, and process upgrades.

1. Material Revolution: A Paradigm Breakthrough from Single Metal to Composite Materials

Traditional bumper molds are primarily made of steel, but its high density limits the potential for lightweighting. In the era of new energy vehicles, mold materials are undergoing a leapfrog upgrade from "weight reduction" to "efficiency improvement":

Application of Carbon Fiber Composite Materials

Carbon fiber, with its "specific strength six times that of steel," has become a core material for high-end bumper molds. For example, HRC's aerodynamic rear bumper assembly mold utilizes 0.8mm thin-wall molding technology, reducing the mold weight to 58% of traditional plastic molds while maintaining impact resistance. A more cutting-edge exploration lies in the combination of carbon fiber and thermoplastic resins. Shape Corp. developed a curved carbon fiber pultruded bumper beam mold for the Chevrolet Corvette. It weighs only 1.3kg, 50% lighter than the original steel mold. Its multi-cavity design also improves collision energy absorption efficiency by 35%.

Synergistic Innovation with Basalt Fiber

Addressing the high cost of carbon fiber, basalt fiber offers a significant cost-effective solution. A hybrid fiber bumper mold developed by a university utilizes basalt fiber (30%) in the outer layer to enhance UV and salt spray corrosion resistance, and carbon fiber (70%) in the inner layer to ensure structural strength. This reduces the mold's aging rate by 60% across a wide temperature range of -40°C to 80°C, extending its service life to over 15 years. This design reduces overall costs by 25%-30% while maintaining over 85% impact resistance.

Closed-loop recycling of bio-based materials

Pulite's closed-loop recycled modified polypropylene composite mold increases the utilization rate of recycled materials from scrap bumpers to 92%. Through epoxy resin toughening technology, the surface tension of the recycled material is increased from 32mN/m to 45mN/m, allowing it to be directly used in new mold production. This technology reduces the mold's lifecycle carbon footprint by 40% and reduces production costs by 18% compared to virgin materials, making it a model for green manufacturing.

2. Structural Innovation: Intelligent Evolution from Passive Protection to Active Sensing

Lightweighting isn't simply about replacing materials; it's about achieving "weight reduction without sacrificing quality" through structural optimization. New energy vehicle bumper molds are achieving breakthroughs in the following dimensions:

Bionic Design: Balancing Lightweight and Energy Absorption

The bionic variable-wall thin-wall energy-absorbing box mold, designed based on bamboo, achieves a breakthrough by increasing specific energy absorption by 6.2% and reducing peak load by 28.23% through a gradient distribution of diameter, wall thickness, and internode spacing. After adopting this technology, a certain model's bumper system reduced weight by 19.3%, while still meeting the C-NCAP five-star crash test standard.

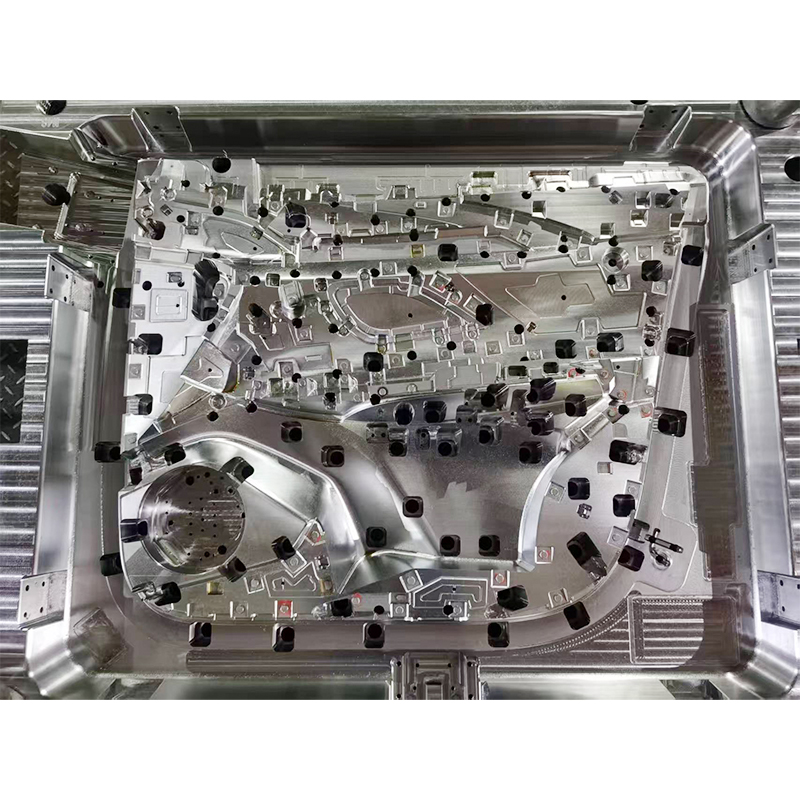

Precision Control of Thin-Wall Technology

Thin-wall technology is a direct means of lightweighting, but it can easily lead to warping and deformation. High-end molds address this issue through the following technologies:

Material Upgrade: Imported pre-hardened steel (such as DIN 1.2738) with a hardness of 30-36 HRC is used, balancing machinability and wear resistance.

Process Optimization: Five-axis high-speed milling achieves ±0.03mm accuracy on complex surfaces, and laser cladding technology repairs worn cavities, extending mold life by over 30%.

Cooling System Innovation: Conformal cooling channel design uses 3D printing technology to create complex, contoured flow channels, improving cooling efficiency by 40%. Zoned temperature control technology implements differentiated cooling strategies for different thickness zones.

Multi-material Co-injection Integrated Manufacturing

Micro-cellular injection molds inject supercritical fluid into the plastic matrix to create a microporous structure, allowing for 15% thinner walls while maintaining structural strength. After adopting this technology in the front bumper mold of a pure electric SUV, the vehicle's weight was reduced by 25kg, and its range increased from 450km to 485km (NEDC operating conditions). Braking energy regeneration efficiency also improved by 3.2%.

3. Process Upgrade: A Paradigm Shift from Traditional Manufacturing to Intelligent Production

New energy vehicles place higher demands on the efficiency, precision, and sustainability of mold processing, driving the industry towards intelligent and automated development.

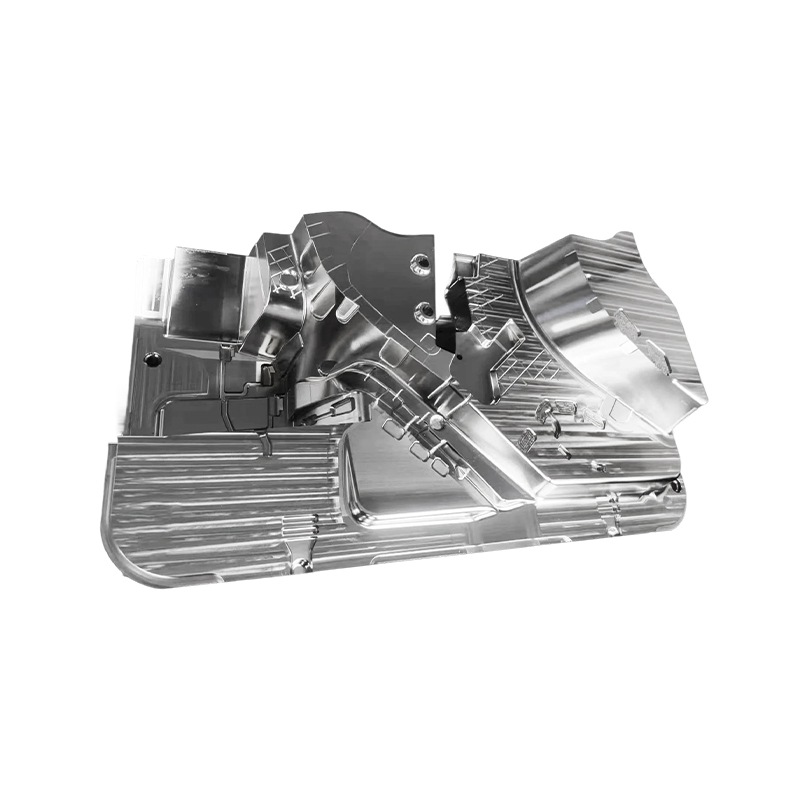

The Appearance Revolution of Internal Parting Technology

Traditional external parting molds expose the parting line on the product's exterior, requiring polishing or painting, impacting cost and consistency. Internal parting molds utilize special track control technology to conceal the parting line on non-exterior surfaces, making the seams between the bumper, hood, and side panels invisible. Although costing 30%-40% more than external parting, this technology is widely adopted by high-end auto brands to enhance exterior quality.

Digital Twin and Intelligent Monitoring

Integrated pressure/temperature sensors within the mold provide real-time monitoring of production status, enabling full lifecycle management through digital twin technology. For example, a company developed an intelligent mold system that can predict mold life and optimize process parameters, increasing production efficiency by 20% and reducing defective product rates by 15%.

Green Transformation to Low-Carbon Processes

To meet the environmental requirements of new energy vehicles, mold processing is promoting low-carbon technologies such as dry cutting and cryogenic cooling. For example, one company replaced traditional cutting fluid with cryogenic coolant, reducing processing energy consumption by 40% and cutting fluid emissions by 90%, saving over one million yuan in annual disposal costs.

4. Market Breakthrough: From Cost Competition to Value Co-creation

The lightweighting breakthrough in new energy vehicle bumper molds is essentially a three-pronged game of technology, cost, and market. Industry-leading companies are building competitive advantages through the following strategies:

Technology Premium and Cost Sharing

Although the initial cost of carbon fiber molds is 30%-40% higher than that of steel molds, they demonstrate significant advantages through full-cycle cost accounting. Over a 10-year lifespan, the average annual maintenance cost of a carbon fiber mold is only 12.5% of that of a steel mold. Furthermore, the annual benefits from improved energy efficiency (electricity savings and increased battery life) reach 12,000 yuan, shortening the payback period to 3.5 years.

Policy Dividends and Market Synergy

China's "New Energy Vehicle Industry Development Plan" explicitly provides purchase subsidies of up to 30% for vehicles using lightweight composite materials. After receiving a 120,000 yuan subsidy per vehicle in a pilot project, the actual cost difference between composite bumper molds and steel components narrowed to 4.6%, accelerating the adoption of this technology.

Personalized Customization and Rapid Response

New energy vehicle consumers are increasingly demanding differentiated appearance, driving mold manufacturing towards a small-batch, high-variety, and fast-delivery model. One company, through modular mold design, reduced mold change time from 8 hours to 2 hours, meeting customer demands for "rapid prototyping in 7 days and mass production in 30 days."

The Future of Lightweighting

In the new energy vehicle era, bumper mold processing has evolved from the 1.0 stage of "material substitution" to the 4.0 stage of deep integration of "materials, structures, processes, and intelligence." In the future, with breakthroughs in cutting-edge technologies such as carbon fiber recycling, AI-driven mold self-optimization systems, and 4D printing deformable molds, bumper molds will achieve the ultimate goal of "lighter, stronger, smarter, and more sustainable," injecting core momentum into the high-quality development of the new energy vehicle industry. In this battle for breakthrough, only companies that use technological innovation as a spear, cost control as a shield, and market demand as a rudder will lead the new lightweighting race.

1. Material Revolution: A Paradigm Breakthrough from Single Metal to Composite Materials

Traditional bumper molds are primarily made of steel, but its high density limits the potential for lightweighting. In the era of new energy vehicles, mold materials are undergoing a leapfrog upgrade from "weight reduction" to "efficiency improvement":

Application of Carbon Fiber Composite Materials

Carbon fiber, with its "specific strength six times that of steel," has become a core material for high-end bumper molds. For example, HRC's aerodynamic rear bumper assembly mold utilizes 0.8mm thin-wall molding technology, reducing the mold weight to 58% of traditional plastic molds while maintaining impact resistance. A more cutting-edge exploration lies in the combination of carbon fiber and thermoplastic resins. Shape Corp. developed a curved carbon fiber pultruded bumper beam mold for the Chevrolet Corvette. It weighs only 1.3kg, 50% lighter than the original steel mold. Its multi-cavity design also improves collision energy absorption efficiency by 35%.

Synergistic Innovation with Basalt Fiber

Addressing the high cost of carbon fiber, basalt fiber offers a significant cost-effective solution. A hybrid fiber bumper mold developed by a university utilizes basalt fiber (30%) in the outer layer to enhance UV and salt spray corrosion resistance, and carbon fiber (70%) in the inner layer to ensure structural strength. This reduces the mold's aging rate by 60% across a wide temperature range of -40°C to 80°C, extending its service life to over 15 years. This design reduces overall costs by 25%-30% while maintaining over 85% impact resistance.

Closed-loop recycling of bio-based materials

Pulite's closed-loop recycled modified polypropylene composite mold increases the utilization rate of recycled materials from scrap bumpers to 92%. Through epoxy resin toughening technology, the surface tension of the recycled material is increased from 32mN/m to 45mN/m, allowing it to be directly used in new mold production. This technology reduces the mold's lifecycle carbon footprint by 40% and reduces production costs by 18% compared to virgin materials, making it a model for green manufacturing.

2. Structural Innovation: Intelligent Evolution from Passive Protection to Active Sensing

Lightweighting isn't simply about replacing materials; it's about achieving "weight reduction without sacrificing quality" through structural optimization. New energy vehicle bumper molds are achieving breakthroughs in the following dimensions:

Bionic Design: Balancing Lightweight and Energy Absorption

The bionic variable-wall thin-wall energy-absorbing box mold, designed based on bamboo, achieves a breakthrough by increasing specific energy absorption by 6.2% and reducing peak load by 28.23% through a gradient distribution of diameter, wall thickness, and internode spacing. After adopting this technology, a certain model's bumper system reduced weight by 19.3%, while still meeting the C-NCAP five-star crash test standard.

Precision Control of Thin-Wall Technology

Thin-wall technology is a direct means of lightweighting, but it can easily lead to warping and deformation. High-end molds address this issue through the following technologies:

Material Upgrade: Imported pre-hardened steel (such as DIN 1.2738) with a hardness of 30-36 HRC is used, balancing machinability and wear resistance.

Process Optimization: Five-axis high-speed milling achieves ±0.03mm accuracy on complex surfaces, and laser cladding technology repairs worn cavities, extending mold life by over 30%.

Cooling System Innovation: Conformal cooling channel design uses 3D printing technology to create complex, contoured flow channels, improving cooling efficiency by 40%. Zoned temperature control technology implements differentiated cooling strategies for different thickness zones.

Multi-material Co-injection Integrated Manufacturing

Micro-cellular injection molds inject supercritical fluid into the plastic matrix to create a microporous structure, allowing for 15% thinner walls while maintaining structural strength. After adopting this technology in the front bumper mold of a pure electric SUV, the vehicle's weight was reduced by 25kg, and its range increased from 450km to 485km (NEDC operating conditions). Braking energy regeneration efficiency also improved by 3.2%.

3. Process Upgrade: A Paradigm Shift from Traditional Manufacturing to Intelligent Production

New energy vehicles place higher demands on the efficiency, precision, and sustainability of mold processing, driving the industry towards intelligent and automated development.

The Appearance Revolution of Internal Parting Technology

Traditional external parting molds expose the parting line on the product's exterior, requiring polishing or painting, impacting cost and consistency. Internal parting molds utilize special track control technology to conceal the parting line on non-exterior surfaces, making the seams between the bumper, hood, and side panels invisible. Although costing 30%-40% more than external parting, this technology is widely adopted by high-end auto brands to enhance exterior quality.

Digital Twin and Intelligent Monitoring

Integrated pressure/temperature sensors within the mold provide real-time monitoring of production status, enabling full lifecycle management through digital twin technology. For example, a company developed an intelligent mold system that can predict mold life and optimize process parameters, increasing production efficiency by 20% and reducing defective product rates by 15%.

Green Transformation to Low-Carbon Processes

To meet the environmental requirements of new energy vehicles, mold processing is promoting low-carbon technologies such as dry cutting and cryogenic cooling. For example, one company replaced traditional cutting fluid with cryogenic coolant, reducing processing energy consumption by 40% and cutting fluid emissions by 90%, saving over one million yuan in annual disposal costs.

4. Market Breakthrough: From Cost Competition to Value Co-creation

The lightweighting breakthrough in new energy vehicle bumper molds is essentially a three-pronged game of technology, cost, and market. Industry-leading companies are building competitive advantages through the following strategies:

Technology Premium and Cost Sharing

Although the initial cost of carbon fiber molds is 30%-40% higher than that of steel molds, they demonstrate significant advantages through full-cycle cost accounting. Over a 10-year lifespan, the average annual maintenance cost of a carbon fiber mold is only 12.5% of that of a steel mold. Furthermore, the annual benefits from improved energy efficiency (electricity savings and increased battery life) reach 12,000 yuan, shortening the payback period to 3.5 years.

Policy Dividends and Market Synergy

China's "New Energy Vehicle Industry Development Plan" explicitly provides purchase subsidies of up to 30% for vehicles using lightweight composite materials. After receiving a 120,000 yuan subsidy per vehicle in a pilot project, the actual cost difference between composite bumper molds and steel components narrowed to 4.6%, accelerating the adoption of this technology.

Personalized Customization and Rapid Response

New energy vehicle consumers are increasingly demanding differentiated appearance, driving mold manufacturing towards a small-batch, high-variety, and fast-delivery model. One company, through modular mold design, reduced mold change time from 8 hours to 2 hours, meeting customer demands for "rapid prototyping in 7 days and mass production in 30 days."

The Future of Lightweighting

In the new energy vehicle era, bumper mold processing has evolved from the 1.0 stage of "material substitution" to the 4.0 stage of deep integration of "materials, structures, processes, and intelligence." In the future, with breakthroughs in cutting-edge technologies such as carbon fiber recycling, AI-driven mold self-optimization systems, and 4D printing deformable molds, bumper molds will achieve the ultimate goal of "lighter, stronger, smarter, and more sustainable," injecting core momentum into the high-quality development of the new energy vehicle industry. In this battle for breakthrough, only companies that use technological innovation as a spear, cost control as a shield, and market demand as a rudder will lead the new lightweighting race.