How to balance the contradiction between cutting performance and wear resistance in the machining of car light molds using high-hardness mold steel?

Release Time : 2026-02-11

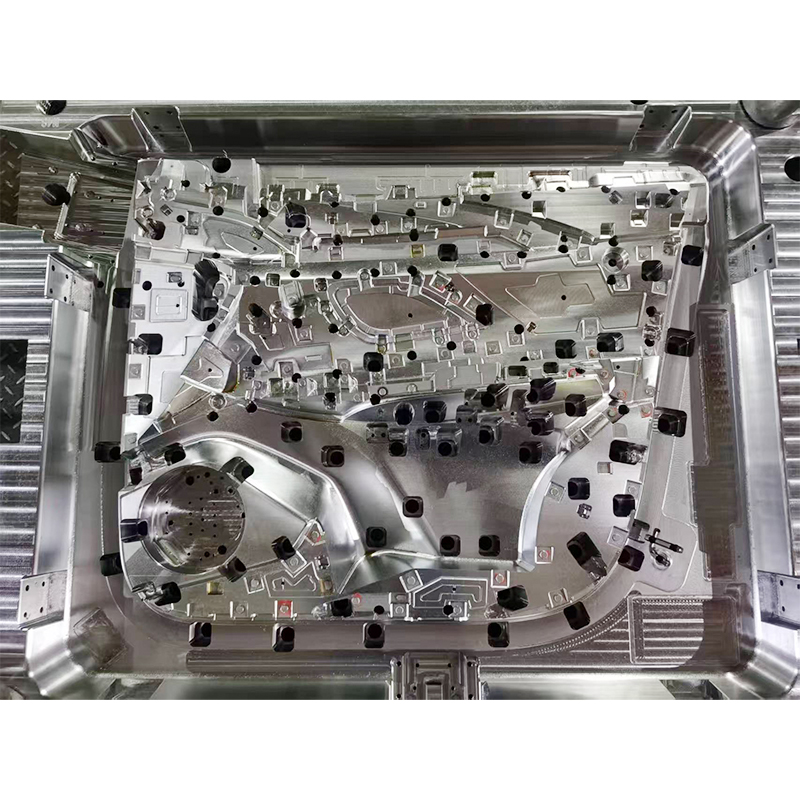

In the field of car light mold processing, high-hardness mold steel is widely used, its core advantage being its ability to meet the high requirements of molds for wear resistance, dimensional stability, and complex surface machining. However, the high hardness directly leads to accelerated tool wear and increased cutting forces during the cutting process, resulting in decreased machining efficiency and unstable surface quality. Therefore, balancing cutting performance and wear resistance is crucial for improving the machining quality of car light molds.

The contradiction between the cutting performance and wear resistance of high-hardness mold steel stems from the conflict between material properties and machining requirements. High-hardness materials (such as those above HRC50) have a dense grain structure, requiring higher energy to break the material during cutting, leading to accelerated wear on the tool rake face. Simultaneously, the low thermal conductivity resulting from high hardness makes it difficult for cutting heat to dissipate, further accelerating tool thermal wear. Wear resistance requires mold steel with high carbide content or special alloying designs. While these hard phases can improve mold life, they also exacerbate friction and impact during cutting, creating a vicious cycle of "the harder, the harder to cut."

Breakthroughs in tool materials and coating technologies have provided a fundamental solution to balancing this contradiction. For high-hardness mold steels, cubic boron nitride (CBN) tools are the preferred choice due to their high hardness and thermal stability, offering significantly superior cutting performance compared to traditional cemented carbide tools. Furthermore, physical vapor deposition (PVD) or chemical vapor deposition (CVD) coating technologies can form a dense alumina or titanium nitride layer on the tool surface, significantly reducing the coefficient of friction and isolating cutting heat, thus extending tool life. For example, CBN tools with a TiAlN coating can achieve several times longer tool life when machining high-hardness steels while maintaining lower cutting forces.

Optimizing cutting parameters is the core means of balancing these trade-offs. By reducing cutting speed, feed rate, and increasing depth of cut, cutting heat generation and stress concentration can be effectively controlled. For example, in the roughing stage, a lower spindle speed and a larger depth of cut are used to quickly remove excess material, reducing the contact time between the tool and the material; in finishing, reducing the feed rate and depth of cut reduces surface roughness and avoids tool overload. In addition, high-pressure coolant jetting technology can significantly improve heat dissipation efficiency, reduce the depth of the heat-affected layer, and further improve the surface quality of the machined material.

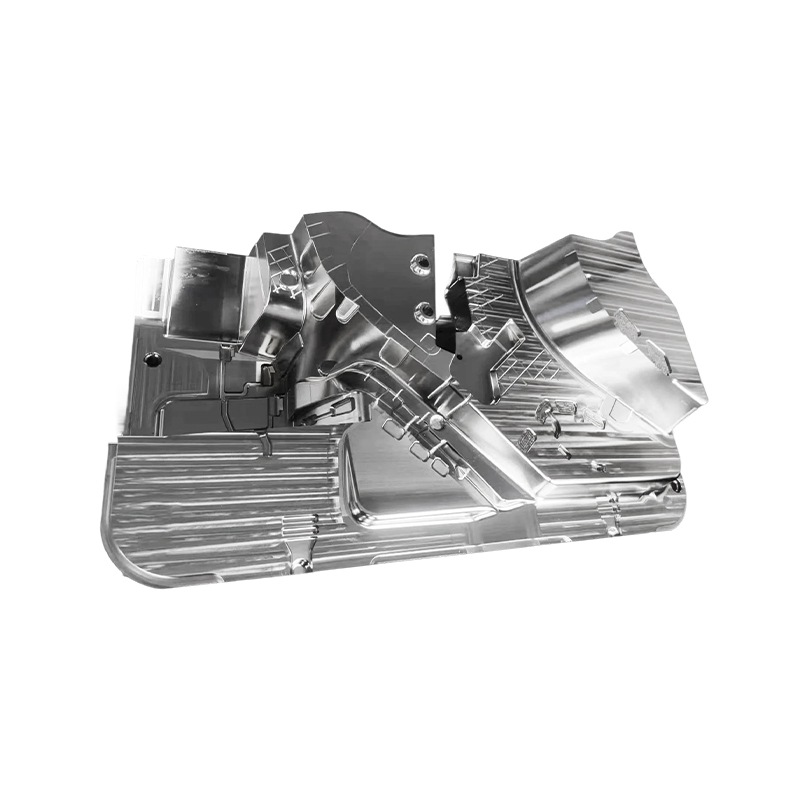

Innovation in machining processes provides new paths to achieving this balance. High-speed milling (HSM) technology reduces tool wear while maintaining high efficiency by increasing spindle speed and feed rate, shortening single-cut time, and reducing heat accumulation per unit volume of material. Vibration cutting technology, on the other hand, applies high-frequency vibrations during cutting, altering the direction and magnitude of cutting forces to induce periodic brittle fracture in hard materials, reducing cutting resistance and improving chip removal. The combined application of these processes significantly improves the machinability of high-hardness mold steels.

The heat treatment process design of mold steel has a decisive impact on the balance between machinability and wear resistance. By optimizing quenching temperature and cooling rate, the grain size and carbide distribution of mold steel can be controlled, ensuring sufficient hardness while avoiding excessive embrittlement. For example, staged quenching or isothermal quenching processes can reduce internal stress and lower the risk of deformation during machining; subsequent low-temperature tempering further improves toughness and reduces the tendency for chipping during cutting.

Surface integrity control is the ultimate goal in balancing these contradictions. The machined surface of high-hardness mold steel must simultaneously meet requirements such as low roughness, absence of microcracks, and residual compressive stress to ensure the wear resistance and fatigue resistance of the mold. By employing ultra-precision cutting processes (such as diamond tool cutting) combined with polishing, a surface roughness Ra < 0.1μm can be achieved. Simultaneously, by controlling cutting parameters and cooling conditions, the formation of surface white layers and microcracks can be avoided, extending the mold's service life.

The balance between the machinability and wear resistance of high-hardness mold steel in car light mold machining requires a multi-dimensional approach, encompassing material selection, tooling technology, parameter optimization, process innovation, heat treatment design, and surface control. Implementing a systematic solution can significantly improve machining efficiency and mold quality, meeting the stringent requirements of the automotive industry for high-precision, long-life molds.