How can the flexible design of plastic molds for car lights meet diverse styling needs and enhance the aesthetic appeal of vehicles?

Release Time : 2026-01-30

In the modern automotive industry, lighting has long transcended its primary function of illumination, becoming a core element defining brand DNA, conveying design language, and enhancing the overall aesthetic value of a vehicle. From streamlined, continuous taillights to sharp, blade-like daytime running lights, from 3D light strips to pixelated interactive matrices, car lights are becoming increasingly complex, sophisticated, and personalized. Behind all this visual innovation lies the high flexibility and precision manufacturing capabilities of plastic mold processing technology.

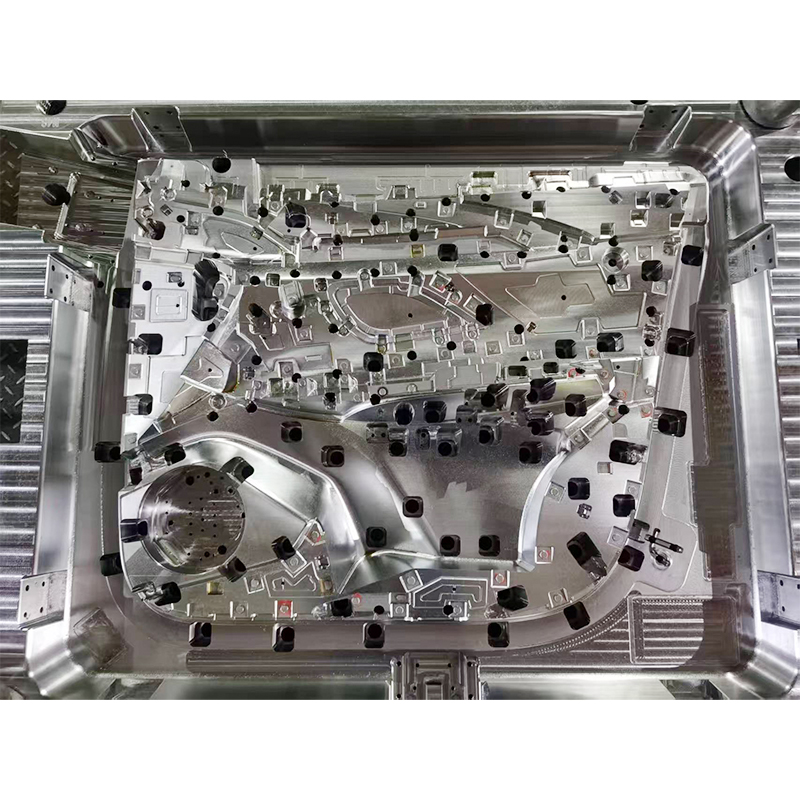

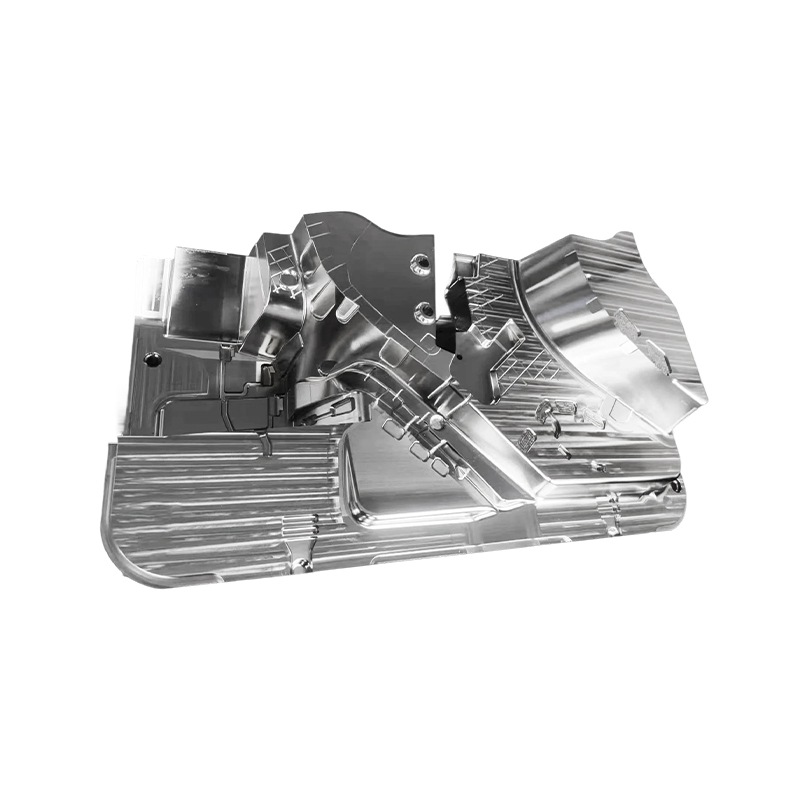

1. Complex Partitioning and Motion Mechanisms Unlock Styling Freedom

Car light covers often contain deep cavities, internal undercuts, curved surface transitions, and micro-clamping structures, making demolding impossible with traditional two-plate molds. Modern plastic molds widely employ multi-directional sliders, angled ejectors, hydraulic core pulling, and even rotary demolding systems, enabling the mold to "intelligently" separate complex geometries during opening and closing. For example, to achieve a continuous, uninterrupted curved surface for a through-type taillight, the mold can be configured with multiple sets of linked sliders that move synchronously along a non-linear trajectory; for headlights with light guides or lens arrays, a micro-angled mechanism can precisely release internal structures at the 0.1–0.3mm level. This dynamic parting capability allows designers to break free from the limitations of the demolding angle, boldly using free-form surfaces, sharp edges, or hollow carvings to give the lamps a sculptural three-dimensional and technological feel.

2. High-Precision Surface Replication to Reproduce Design Details and Texture

The premium feel of lamps stems not only from their shape but also from their surface texture—such as high-gloss piano black, matte finish, brushed metal, or gradient textures. Plastic molds, through ultra-precision machining or laser micro-texturing technology, precisely replicate the design intent on the mold cavity surface. For example, the micron-level dot arrangement of the light guide plate inside Audi's matrix LED headlights is directly formed by the mold, ensuring uniform and soft light; the smoked gradient effect of Lexus taillights is achieved through partial coating or in-mold decorative molding. The mold, or "master template," directly determines the visual appeal and tactile quality of the final product.

3. Multi-material and Multi-color Injection Molding Integration Expands Aesthetic Boundaries

To integrate functional zoning and visual unity, dual-color or multi-material injection molding technology is widely used. A single mold integrates multiple injection units, capable of molding a transparent PC outer shell and a black light-shielding frame in one piece, or a soft TPU decorative strip and a rigid PMMA lampshade. This not only eliminates subsequent bonding processes but also achieves a seamless visual transition. For example, BMW's "L-shaped" daytime running lights create a floating light strip through layered injection molding of transparent and semi-transparent materials; Tesla's taillights utilize red/transparent dual-color molding to construct a simple yet profound luminous graphic. Precise mold alignment is key to the success of such designs.

4. Rapid Iteration and Modular Strategies Accelerate Design Implementation

Faced with shortened automotive R&D cycles and the trend towards personalized customization, mold development must balance efficiency and flexibility. Adopting standardized mold bases, replaceable inserts, and 3D-printed conformal cooling water channels can reduce the manufacturing cycle by more than 30%. Platform-based mold strategies allow the same basic structure to be adapted to different car models—only minor changes to the cavity can create a family-style lighting system. This enables OEMs to quickly respond to changes in market aesthetics, launch exclusive lighting designs, and strengthen brand visual identity.

5. Simulation-Driven Optimization Balances Aesthetics and Engineering Feasibility

In the early design stages, CAE mold flow analysis can predict weld lines, warpage, and shrinkage marks, guiding designers to adjust wall thickness and gate layout. For example, to eliminate weld lines running through the center of the light, a hot runner needle valve gate is used to simultaneously inject material from both ends; for thin-walled areas, conformal cooling water channels ensure uniform heat dissipation and prevent imperfections on high-gloss surfaces. This closed-loop "design-simulation-manufacturing" process allows aesthetic ideas to be precisely implemented in engineering reality.

In conclusion, plastic mold processing technology, with its high flexibility, precision, and integration capabilities, has become the core support for innovative car light designs. It not only solves the manufacturing challenges of complex structures, but also transforms the designer's aesthetic vision into a mass-producible reality, making each headlight a shining brand name card in the night, and continuously promoting the integration of art and technology in automotive exterior design to a higher level.

1. Complex Partitioning and Motion Mechanisms Unlock Styling Freedom

Car light covers often contain deep cavities, internal undercuts, curved surface transitions, and micro-clamping structures, making demolding impossible with traditional two-plate molds. Modern plastic molds widely employ multi-directional sliders, angled ejectors, hydraulic core pulling, and even rotary demolding systems, enabling the mold to "intelligently" separate complex geometries during opening and closing. For example, to achieve a continuous, uninterrupted curved surface for a through-type taillight, the mold can be configured with multiple sets of linked sliders that move synchronously along a non-linear trajectory; for headlights with light guides or lens arrays, a micro-angled mechanism can precisely release internal structures at the 0.1–0.3mm level. This dynamic parting capability allows designers to break free from the limitations of the demolding angle, boldly using free-form surfaces, sharp edges, or hollow carvings to give the lamps a sculptural three-dimensional and technological feel.

2. High-Precision Surface Replication to Reproduce Design Details and Texture

The premium feel of lamps stems not only from their shape but also from their surface texture—such as high-gloss piano black, matte finish, brushed metal, or gradient textures. Plastic molds, through ultra-precision machining or laser micro-texturing technology, precisely replicate the design intent on the mold cavity surface. For example, the micron-level dot arrangement of the light guide plate inside Audi's matrix LED headlights is directly formed by the mold, ensuring uniform and soft light; the smoked gradient effect of Lexus taillights is achieved through partial coating or in-mold decorative molding. The mold, or "master template," directly determines the visual appeal and tactile quality of the final product.

3. Multi-material and Multi-color Injection Molding Integration Expands Aesthetic Boundaries

To integrate functional zoning and visual unity, dual-color or multi-material injection molding technology is widely used. A single mold integrates multiple injection units, capable of molding a transparent PC outer shell and a black light-shielding frame in one piece, or a soft TPU decorative strip and a rigid PMMA lampshade. This not only eliminates subsequent bonding processes but also achieves a seamless visual transition. For example, BMW's "L-shaped" daytime running lights create a floating light strip through layered injection molding of transparent and semi-transparent materials; Tesla's taillights utilize red/transparent dual-color molding to construct a simple yet profound luminous graphic. Precise mold alignment is key to the success of such designs.

4. Rapid Iteration and Modular Strategies Accelerate Design Implementation

Faced with shortened automotive R&D cycles and the trend towards personalized customization, mold development must balance efficiency and flexibility. Adopting standardized mold bases, replaceable inserts, and 3D-printed conformal cooling water channels can reduce the manufacturing cycle by more than 30%. Platform-based mold strategies allow the same basic structure to be adapted to different car models—only minor changes to the cavity can create a family-style lighting system. This enables OEMs to quickly respond to changes in market aesthetics, launch exclusive lighting designs, and strengthen brand visual identity.

5. Simulation-Driven Optimization Balances Aesthetics and Engineering Feasibility

In the early design stages, CAE mold flow analysis can predict weld lines, warpage, and shrinkage marks, guiding designers to adjust wall thickness and gate layout. For example, to eliminate weld lines running through the center of the light, a hot runner needle valve gate is used to simultaneously inject material from both ends; for thin-walled areas, conformal cooling water channels ensure uniform heat dissipation and prevent imperfections on high-gloss surfaces. This closed-loop "design-simulation-manufacturing" process allows aesthetic ideas to be precisely implemented in engineering reality.

In conclusion, plastic mold processing technology, with its high flexibility, precision, and integration capabilities, has become the core support for innovative car light designs. It not only solves the manufacturing challenges of complex structures, but also transforms the designer's aesthetic vision into a mass-producible reality, making each headlight a shining brand name card in the night, and continuously promoting the integration of art and technology in automotive exterior design to a higher level.