How do hot runner systems improve fender mold production efficiency?

Release Time : 2025-09-12

In the precision chain of modern automotive manufacturing, the car fender mold, with its massive size and meticulous craftsmanship, serves as an "invisible sculptor" shaping the vehicle's contours. It's more than just a tool for producing plastic parts; it's a complex work of art that blends industrial aesthetics, fluid dynamics, and intelligent manufacturing. With every moment of mold closing and opening, it silently sculpts the vehicle's practicality and style.

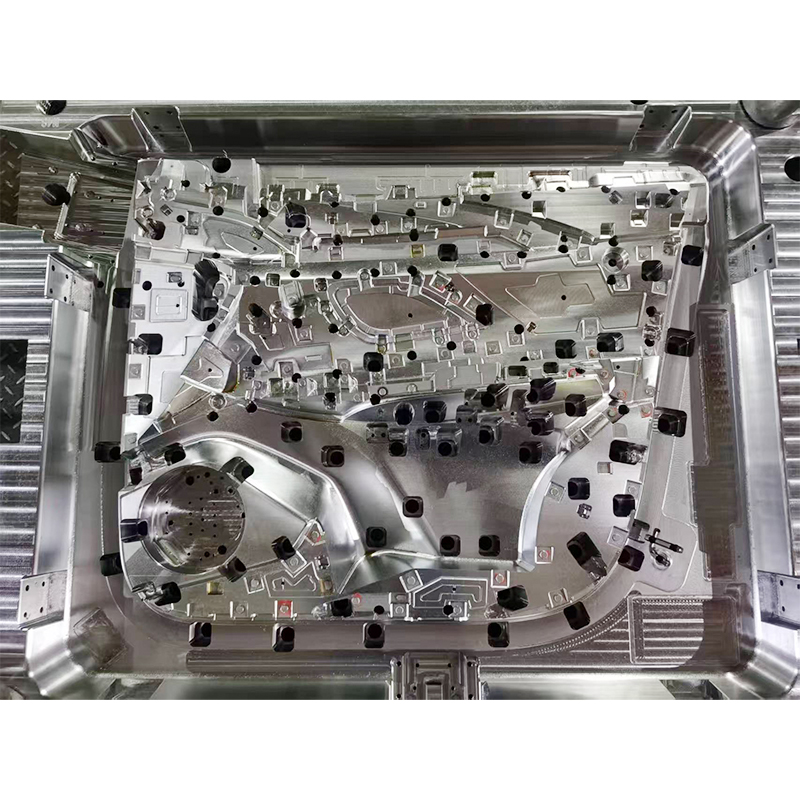

The charm of a car fender mold lies first in its magnificent symphony of structural beauty and meticulous detail. Externally, it's often constructed from massive alloy steel modules, their surfaces precision-ground and mirror-polished to a cool, deep metallic luster. The massive mold frame boasts a rigorous structure, precise alignment of guide pins and bushings, a strategically placed cooling system, and distinct interfaces for hydraulic and pneumatic systems. The overall design exudes a sense of power and order unique to industrial machinery. As the mold slowly closes, the seamless fit resembles the perfect integration of two intricate puzzle pieces, demonstrating the ultimate pursuit of manufacturing excellence. Even more impressive is its inherent sophistication—the mold cavity surface replicates every curve, ridge, and texture of the final fender. Whether it's the smooth curved contours to accommodate wheel rotation, the strategically placed internal ribs to enhance structural strength, or the subtle grain and finish to complement the vehicle's interior, each is repeatedly simulated and optimized using 3D software to ensure the molded product is dimensionally precise, aesthetically flawless, and seamlessly integrated with the vehicle body. This comprehensive control, from macroscopic structure to microscopic detail, is the crystallization of the wisdom of industrial design and manufacturing.

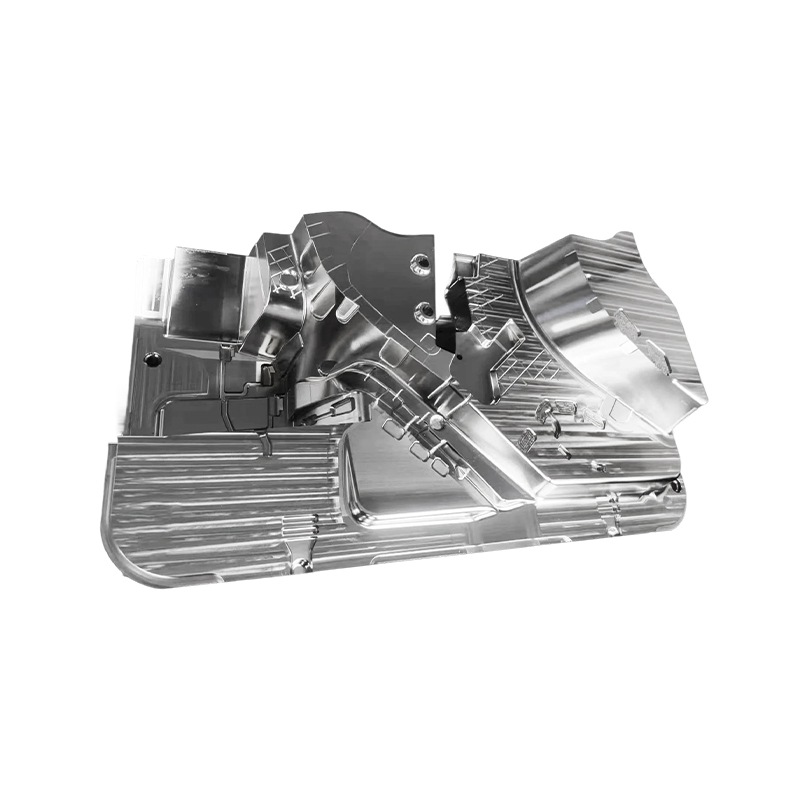

The innovation lies in the deep fusion of "functional integration" and "efficient production." The wisdom of the car fender mold lies not only in the molding process but also in the efficient and stable mass production. Modern molds commonly utilize hot runner systems, which inject molten plastic directly and evenly into the mold cavity, eliminating the formation of cold slugs, reducing material waste, and improving production efficiency. Complex ejector mechanisms, such as multi-stage ejectors, push plates, or pneumatic ejectors, ensure that large, deep-cavity fenders are smoothly and seamlessly removed from the mold cavity after mold opening, avoiding deformation or scratches. Even more innovative is its intelligent monitoring system—built-in temperature and pressure sensors collect real-time mold cavity data, interacting with the injection molding machine to achieve closed-loop control of process parameters, ensuring highly consistent quality for every product. Some high-end molds also feature automatic cleaning and lubrication functions, further reducing downtime and maintenance, adapting to the production needs of modern, unmanned workshops.

The company's advantages are deeply rooted in the dual values of "quality assurance" and "cost optimization." The most significant advantage lies in its decisive impact on product performance. High-quality car fender molds ensure precise dimensional tolerances, excellent surface quality, and sufficient mechanical strength for the fenders produced. They effectively block mud, water, and debris kicked up by wheels, protecting the body paint and chassis components, and extending the vehicle's service life. Furthermore, the mold's long life and high stability mean lower unit production costs and higher equipment utilization. By optimizing the cooling system and flow channel design, we shorten the molding cycle and achieve "fast, accurate, and stable" continuous production, meeting the high-volume, high-paced assembly needs of OEMs.

The car fender mold is the "unsung mastermind" of the automotive industry. Its steel skeleton supports the production of millions of fenders; its precise mold cavity replicates the perfect body lines; its intelligent systems ensure stable and efficient production; and its silent operation protects the cleanliness and safety of every vehicle. As it works tirelessly day and night in the automated workshop, the collision of metal and the molding of plastic write a magnificent chapter in modern manufacturing. Choosing a car fender mold means choosing a cornerstone of reliability and efficiency for automotive production. Its massive size embodies precision, its silence drives production. Utilizing the most advanced design concepts, the most rigorous processing techniques, and the most intelligent control systems, it transforms design drawings into reliable automotive components. It is an indispensable "core equipment" in the modern automotive industry chain.

The charm of a car fender mold lies first in its magnificent symphony of structural beauty and meticulous detail. Externally, it's often constructed from massive alloy steel modules, their surfaces precision-ground and mirror-polished to a cool, deep metallic luster. The massive mold frame boasts a rigorous structure, precise alignment of guide pins and bushings, a strategically placed cooling system, and distinct interfaces for hydraulic and pneumatic systems. The overall design exudes a sense of power and order unique to industrial machinery. As the mold slowly closes, the seamless fit resembles the perfect integration of two intricate puzzle pieces, demonstrating the ultimate pursuit of manufacturing excellence. Even more impressive is its inherent sophistication—the mold cavity surface replicates every curve, ridge, and texture of the final fender. Whether it's the smooth curved contours to accommodate wheel rotation, the strategically placed internal ribs to enhance structural strength, or the subtle grain and finish to complement the vehicle's interior, each is repeatedly simulated and optimized using 3D software to ensure the molded product is dimensionally precise, aesthetically flawless, and seamlessly integrated with the vehicle body. This comprehensive control, from macroscopic structure to microscopic detail, is the crystallization of the wisdom of industrial design and manufacturing.

The innovation lies in the deep fusion of "functional integration" and "efficient production." The wisdom of the car fender mold lies not only in the molding process but also in the efficient and stable mass production. Modern molds commonly utilize hot runner systems, which inject molten plastic directly and evenly into the mold cavity, eliminating the formation of cold slugs, reducing material waste, and improving production efficiency. Complex ejector mechanisms, such as multi-stage ejectors, push plates, or pneumatic ejectors, ensure that large, deep-cavity fenders are smoothly and seamlessly removed from the mold cavity after mold opening, avoiding deformation or scratches. Even more innovative is its intelligent monitoring system—built-in temperature and pressure sensors collect real-time mold cavity data, interacting with the injection molding machine to achieve closed-loop control of process parameters, ensuring highly consistent quality for every product. Some high-end molds also feature automatic cleaning and lubrication functions, further reducing downtime and maintenance, adapting to the production needs of modern, unmanned workshops.

The company's advantages are deeply rooted in the dual values of "quality assurance" and "cost optimization." The most significant advantage lies in its decisive impact on product performance. High-quality car fender molds ensure precise dimensional tolerances, excellent surface quality, and sufficient mechanical strength for the fenders produced. They effectively block mud, water, and debris kicked up by wheels, protecting the body paint and chassis components, and extending the vehicle's service life. Furthermore, the mold's long life and high stability mean lower unit production costs and higher equipment utilization. By optimizing the cooling system and flow channel design, we shorten the molding cycle and achieve "fast, accurate, and stable" continuous production, meeting the high-volume, high-paced assembly needs of OEMs.

The car fender mold is the "unsung mastermind" of the automotive industry. Its steel skeleton supports the production of millions of fenders; its precise mold cavity replicates the perfect body lines; its intelligent systems ensure stable and efficient production; and its silent operation protects the cleanliness and safety of every vehicle. As it works tirelessly day and night in the automated workshop, the collision of metal and the molding of plastic write a magnificent chapter in modern manufacturing. Choosing a car fender mold means choosing a cornerstone of reliability and efficiency for automotive production. Its massive size embodies precision, its silence drives production. Utilizing the most advanced design concepts, the most rigorous processing techniques, and the most intelligent control systems, it transforms design drawings into reliable automotive components. It is an indispensable "core equipment" in the modern automotive industry chain.