What are the advantages of car door panel mold processing in improving surface finish?

Release Time : 2025-09-25

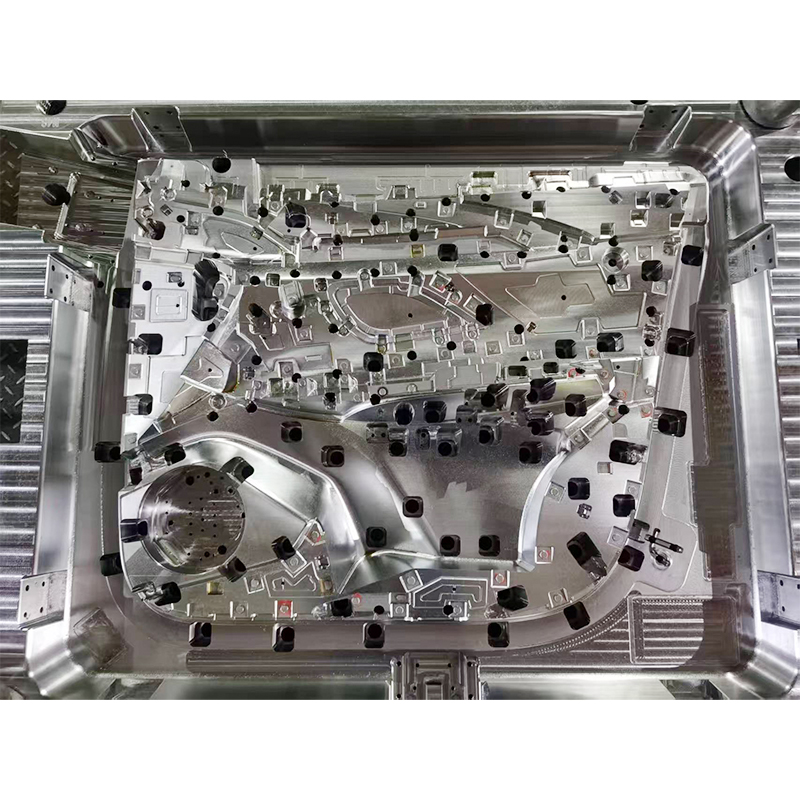

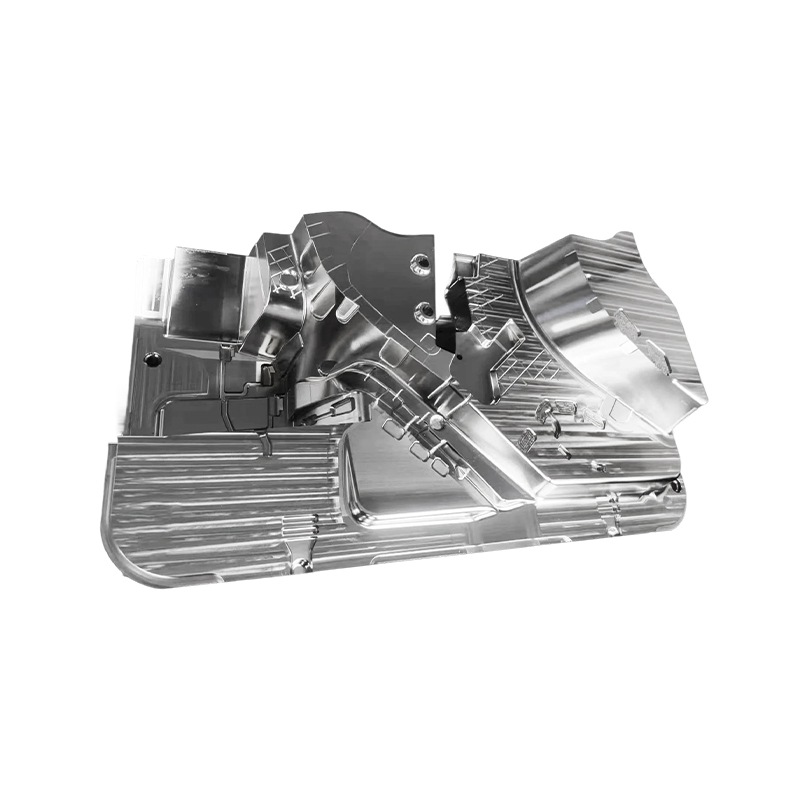

As a crucial component of vehicle interiors, the appearance and quality of car door panels directly impact the overall vehicle's quality and user experience. The surface quality of door panels depends entirely on the mold's machining precision and surface finish. Modern car door panel mold processing technology, leveraging advanced equipment, precise processes, and scientific process management, demonstrates significant advantages in improving mold surface finish, providing a solid foundation for the mass production of high-quality interior components.

1. High-speed milling technology achieves mirror-quality results

High-speed milling is a core process for improving mold surface finish. Compared to traditional low-speed cutting, high-speed milling utilizes higher spindle speeds and feed rates, coupled with a small depth of cut and fast tool movement. This creates extremely fine cutting marks on the material surface, significantly reducing surface roughness. Furthermore, most of the heat generated by high-speed cutting is quickly dissipated with the chips, minimizing thermal deformation in the workpiece and preventing surface ripples or burns caused by temperature rise. For large curved surfaces in door panel molds, high-speed milling significantly reduces the workload of subsequent manual polishing and can even replace polishing with milling, ensuring surface consistency.

2. Five-axis simultaneous machining ensures a continuous and smooth finish on complex surfaces

Car door panel molds often contain complex free-form surfaces, rounded corner transitions, and fine edges. Traditional three-axis machine tools are prone to tool marks and inconsistent tool traces when machining these areas. Five-axis simultaneous machining technology simultaneously controls the tool's motion in five directions, ensuring that the tool always contacts the workpiece surface at the optimal angle, achieving a continuous and smooth cutting path. This machining method not only improves the geometric accuracy of complex areas but also effectively avoids surface defects caused by tool tilting or tool changes. It ensures a uniform finish across the entire mold cavity, providing a foundation for perfect surface replication of injection molded parts.

3. Precision Tooling and Coating Technologies Improve Cutting Stability

Mold surface finish is closely related to tool performance. Modern door panel mold machining widely utilizes high-precision solid carbide tools or indexable milling inserts with precision-ground cutting edges to ensure smooth cutting. Furthermore, high-performance coatings such as TiAlN and AlCrN on the tool surface not only improve wear resistance and high-temperature resistance, but also reduce friction, minimize chip adhesion, and prevent surface damage caused by "built-up edge." A stable cutting process means less vibration and a more uniform surface texture, directly improving the mold's finish.

4. Automation and digital control reduce human error

Car door panel mold processing generally utilizes automated production lines and digital control systems. From blank clamping to multi-step processing, precision vises, hydraulic clamps, or reference hole positioning systems achieve high repeatability. CNC systems precisely control cutting parameters at each step, preventing overcutting, chattering, and surface scratches caused by improper operation. Furthermore, in-process measurement and error compensation technologies monitor surface quality in real time, enabling timely adjustments to machining strategies to ensure that the final product meets stringent finish standards.

5. Fine polishing and surface treatment enhance final quality

Although modern machining techniques can achieve extremely high finishes, door panel molds for high-end models still require meticulous manual or mechanical polishing. Thanks to the high-precision milling foundation established earlier, only minor polishing adjustments are required during the polishing process to achieve a super-mirror finish of less than Ra 0.05μm. The mold can also undergo surface treatments such as chrome plating and nitriding to further enhance hardness and gloss, wear resistance, and mold release. These post-processing steps, performed on a foundation of high-quality machining, provide greater efficiency and more consistent results.

6. Rigorous Quality Inspection Ensures Surface Finish

After mold processing is complete, key areas are inspected using a high-precision coordinate measuring machine, surface roughness tester, and optical scanning equipment to ensure surface finish meets design requirements. Digital inspection data is traceable and analyzable, providing a basis for process optimization and establishing a closed-loop quality control system.

In summary, the car door panel mold processing utilizes a multi-faceted technology synergistically, including high-speed milling, five-axis machining, precision tooling, automated control, fine polishing, and rigorous inspection, to comprehensively improve mold surface finish. This not only shortens production cycle time and reduces labor costs, but more importantly, provides a high-quality matrix for injection molding, ensuring that each car door panel has a delicate, uniform, and high-end surface texture, meeting consumers' increasingly sophisticated aesthetic and quality requirements for automotive interiors.

1. High-speed milling technology achieves mirror-quality results

High-speed milling is a core process for improving mold surface finish. Compared to traditional low-speed cutting, high-speed milling utilizes higher spindle speeds and feed rates, coupled with a small depth of cut and fast tool movement. This creates extremely fine cutting marks on the material surface, significantly reducing surface roughness. Furthermore, most of the heat generated by high-speed cutting is quickly dissipated with the chips, minimizing thermal deformation in the workpiece and preventing surface ripples or burns caused by temperature rise. For large curved surfaces in door panel molds, high-speed milling significantly reduces the workload of subsequent manual polishing and can even replace polishing with milling, ensuring surface consistency.

2. Five-axis simultaneous machining ensures a continuous and smooth finish on complex surfaces

Car door panel molds often contain complex free-form surfaces, rounded corner transitions, and fine edges. Traditional three-axis machine tools are prone to tool marks and inconsistent tool traces when machining these areas. Five-axis simultaneous machining technology simultaneously controls the tool's motion in five directions, ensuring that the tool always contacts the workpiece surface at the optimal angle, achieving a continuous and smooth cutting path. This machining method not only improves the geometric accuracy of complex areas but also effectively avoids surface defects caused by tool tilting or tool changes. It ensures a uniform finish across the entire mold cavity, providing a foundation for perfect surface replication of injection molded parts.

3. Precision Tooling and Coating Technologies Improve Cutting Stability

Mold surface finish is closely related to tool performance. Modern door panel mold machining widely utilizes high-precision solid carbide tools or indexable milling inserts with precision-ground cutting edges to ensure smooth cutting. Furthermore, high-performance coatings such as TiAlN and AlCrN on the tool surface not only improve wear resistance and high-temperature resistance, but also reduce friction, minimize chip adhesion, and prevent surface damage caused by "built-up edge." A stable cutting process means less vibration and a more uniform surface texture, directly improving the mold's finish.

4. Automation and digital control reduce human error

Car door panel mold processing generally utilizes automated production lines and digital control systems. From blank clamping to multi-step processing, precision vises, hydraulic clamps, or reference hole positioning systems achieve high repeatability. CNC systems precisely control cutting parameters at each step, preventing overcutting, chattering, and surface scratches caused by improper operation. Furthermore, in-process measurement and error compensation technologies monitor surface quality in real time, enabling timely adjustments to machining strategies to ensure that the final product meets stringent finish standards.

5. Fine polishing and surface treatment enhance final quality

Although modern machining techniques can achieve extremely high finishes, door panel molds for high-end models still require meticulous manual or mechanical polishing. Thanks to the high-precision milling foundation established earlier, only minor polishing adjustments are required during the polishing process to achieve a super-mirror finish of less than Ra 0.05μm. The mold can also undergo surface treatments such as chrome plating and nitriding to further enhance hardness and gloss, wear resistance, and mold release. These post-processing steps, performed on a foundation of high-quality machining, provide greater efficiency and more consistent results.

6. Rigorous Quality Inspection Ensures Surface Finish

After mold processing is complete, key areas are inspected using a high-precision coordinate measuring machine, surface roughness tester, and optical scanning equipment to ensure surface finish meets design requirements. Digital inspection data is traceable and analyzable, providing a basis for process optimization and establishing a closed-loop quality control system.

In summary, the car door panel mold processing utilizes a multi-faceted technology synergistically, including high-speed milling, five-axis machining, precision tooling, automated control, fine polishing, and rigorous inspection, to comprehensively improve mold surface finish. This not only shortens production cycle time and reduces labor costs, but more importantly, provides a high-quality matrix for injection molding, ensuring that each car door panel has a delicate, uniform, and high-end surface texture, meeting consumers' increasingly sophisticated aesthetic and quality requirements for automotive interiors.