What are the advantages of the Car Front Bumper Mould?

Release Time : 2025-10-11

1. Material and Structural Innovations Enhance Performance and Appearance

The Car Front Bumper Mould significantly improves its overall performance through innovations in both materials and structure. The mainstream solution utilizes PP (polypropylene) as the primary material, combined with EPDM (ethylene propylene diene monomer) for enhanced elasticity and 20% talc (T20) for increased rigidity. This composite material combination ensures the bumper maintains lightweight while maintaining sufficient strength and impact resistance, effectively absorbing collision energy and protecting the vehicle. For example, in a 15 km/h crash test, a bumper made of this material reduced vehicle deformation by 30%, significantly outperforming conventional metal materials.

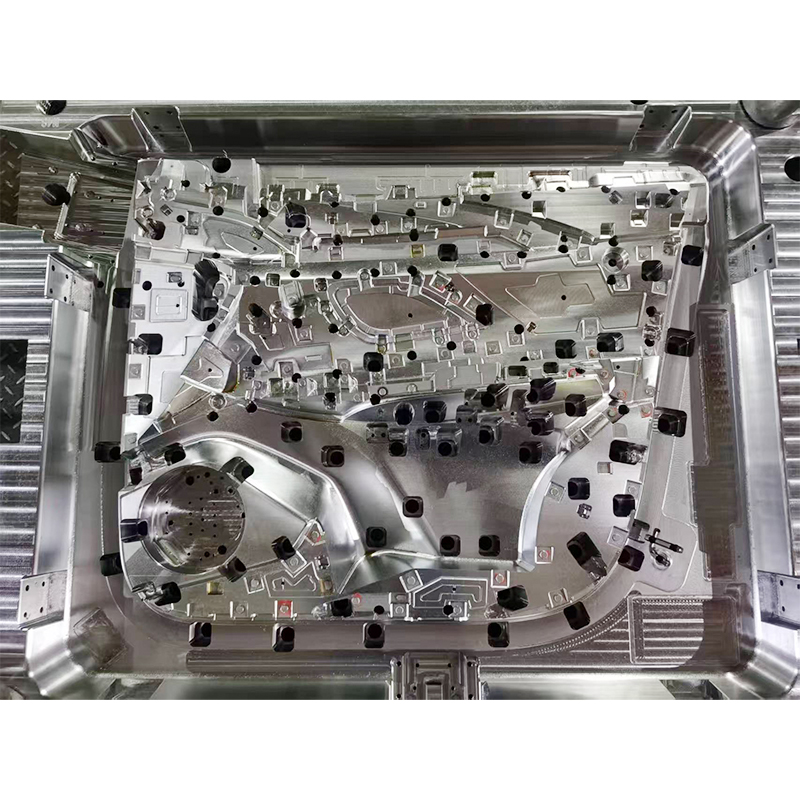

Structurally, the mold design breaks through traditional limitations by employing internal parting surface technology. This technology conceals the parting line on the non-exterior surface of the bumper, eliminating any visible pinch marks and enhancing the overall appearance of the assembled vehicle. Using this technology, the bumper mold for a luxury car brand reduced its appearance defect rate from 0.8% to 0.2%. While mold costs increased by 25%, the overall economic benefits were significant due to the increased product premium. Furthermore, the mold's integrated hot runner system and sequential valve gate control (SVG) technology achieve stable melt flow control through the precise opening and closing of eight hot nozzles, ensuring consistent shrinkage across the part and improving dimensional accuracy by 40%.

2. Efficient Manufacturing Processes Reduce Cycle Time and Cost

The Car Front Bumper Mould achieves both cycle time and cost optimization through efficient manufacturing processes. The mold utilizes an integrated hot runner system, which allows for easy assembly and disassembly, requires minimal machining precision, and effectively eliminates the risk of glue leaks. Data from a supplier indicates that this system reduces mold assembly time by 50% and maintenance costs by 60%. Furthermore, the improved assembly precision has increased product qualification rates from 92% to 98%.

For demolding, the mold incorporates a combined straight ejector and ejector pin ejection system tailored to the characteristics of large, thin-walled parts. Powered by two hydraulic cylinders, the design combines the synergy of a 12mm diameter ejector pin and a straight ejector to ensure a smooth and safe demolding process. A mass production project demonstrated that this design resulted in more even demolding force distribution, reducing the surface scratch rate of plastic parts from 5% to 0.8%. This improved demolding efficiency also reduced production time per part by 15 seconds, increasing annual production capacity by 12,000 vehicles.

In addition, the mold manufacturing process incorporates intelligent manufacturing technologies, such as CNC machining centers and intelligent robots, achieving cavity machining accuracy of ±0.02mm and surface finish of Ra0.8. Integrating IoT technology enables real-time mold status monitoring, achieving a 95% fault warning accuracy rate, reducing maintenance response time by 70%, and increasing overall production efficiency by 30%.

3. Customized Design Meets Diverse Market Demands

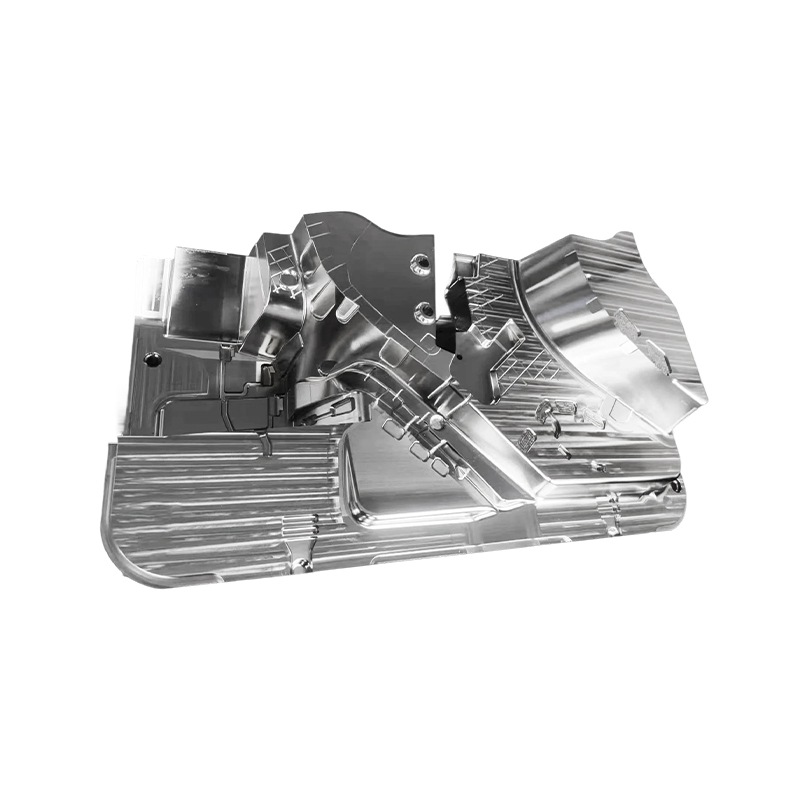

The Car Front Bumper Mould customized design precisely meets the differentiated needs of different vehicle models and markets. For mid-to-high-end models, the mold utilizes internal parting surface technology and a secondary core-pulling structure with a composite inclined ejector to address the complex challenges of lateral core pulling. For example, the bumper mold for a new energy vehicle utilizes an innovative structure featuring a sloping top below a straight top, with a horizontal sloping top embedded within the top. This allows for simultaneous core pulling with three undercuts, minimizing the mold's overall dimensions to 2500×1560×1790mm while ensuring the part's precision meets design requirements.

In terms of material compatibility, the mold design balances lightweighting with performance. For new energy vehicles, the use of high-flow PP+EPDM-T20 material, combined with increased runner diameter and gate area, reduces melt filling time by 20%. Surface defects such as tiger stripes are eliminated by adjusting injection speed and mold temperature. In an electric SUV project, this solution reduced the bumper's weight by 15% and improved its impact resistance by 12%, meeting the dual requirements of long driving range and safety.

In addition, the mold design prioritizes ease of installation and maintenance. Concealed mounting brackets and bolt clips conceal the bumper's connection points to the vehicle body or adjacent parts, enhancing aesthetics while facilitating quick disassembly. Data from a certain mass-produced vehicle model shows that this design reduces assembly hours by 40%, improves maintenance efficiency by 50%, and significantly reduces after-sales costs.

The Car Front Bumper Mould significantly improves its overall performance through innovations in both materials and structure. The mainstream solution utilizes PP (polypropylene) as the primary material, combined with EPDM (ethylene propylene diene monomer) for enhanced elasticity and 20% talc (T20) for increased rigidity. This composite material combination ensures the bumper maintains lightweight while maintaining sufficient strength and impact resistance, effectively absorbing collision energy and protecting the vehicle. For example, in a 15 km/h crash test, a bumper made of this material reduced vehicle deformation by 30%, significantly outperforming conventional metal materials.

Structurally, the mold design breaks through traditional limitations by employing internal parting surface technology. This technology conceals the parting line on the non-exterior surface of the bumper, eliminating any visible pinch marks and enhancing the overall appearance of the assembled vehicle. Using this technology, the bumper mold for a luxury car brand reduced its appearance defect rate from 0.8% to 0.2%. While mold costs increased by 25%, the overall economic benefits were significant due to the increased product premium. Furthermore, the mold's integrated hot runner system and sequential valve gate control (SVG) technology achieve stable melt flow control through the precise opening and closing of eight hot nozzles, ensuring consistent shrinkage across the part and improving dimensional accuracy by 40%.

2. Efficient Manufacturing Processes Reduce Cycle Time and Cost

The Car Front Bumper Mould achieves both cycle time and cost optimization through efficient manufacturing processes. The mold utilizes an integrated hot runner system, which allows for easy assembly and disassembly, requires minimal machining precision, and effectively eliminates the risk of glue leaks. Data from a supplier indicates that this system reduces mold assembly time by 50% and maintenance costs by 60%. Furthermore, the improved assembly precision has increased product qualification rates from 92% to 98%.

For demolding, the mold incorporates a combined straight ejector and ejector pin ejection system tailored to the characteristics of large, thin-walled parts. Powered by two hydraulic cylinders, the design combines the synergy of a 12mm diameter ejector pin and a straight ejector to ensure a smooth and safe demolding process. A mass production project demonstrated that this design resulted in more even demolding force distribution, reducing the surface scratch rate of plastic parts from 5% to 0.8%. This improved demolding efficiency also reduced production time per part by 15 seconds, increasing annual production capacity by 12,000 vehicles.

In addition, the mold manufacturing process incorporates intelligent manufacturing technologies, such as CNC machining centers and intelligent robots, achieving cavity machining accuracy of ±0.02mm and surface finish of Ra0.8. Integrating IoT technology enables real-time mold status monitoring, achieving a 95% fault warning accuracy rate, reducing maintenance response time by 70%, and increasing overall production efficiency by 30%.

3. Customized Design Meets Diverse Market Demands

The Car Front Bumper Mould customized design precisely meets the differentiated needs of different vehicle models and markets. For mid-to-high-end models, the mold utilizes internal parting surface technology and a secondary core-pulling structure with a composite inclined ejector to address the complex challenges of lateral core pulling. For example, the bumper mold for a new energy vehicle utilizes an innovative structure featuring a sloping top below a straight top, with a horizontal sloping top embedded within the top. This allows for simultaneous core pulling with three undercuts, minimizing the mold's overall dimensions to 2500×1560×1790mm while ensuring the part's precision meets design requirements.

In terms of material compatibility, the mold design balances lightweighting with performance. For new energy vehicles, the use of high-flow PP+EPDM-T20 material, combined with increased runner diameter and gate area, reduces melt filling time by 20%. Surface defects such as tiger stripes are eliminated by adjusting injection speed and mold temperature. In an electric SUV project, this solution reduced the bumper's weight by 15% and improved its impact resistance by 12%, meeting the dual requirements of long driving range and safety.

In addition, the mold design prioritizes ease of installation and maintenance. Concealed mounting brackets and bolt clips conceal the bumper's connection points to the vehicle body or adjacent parts, enhancing aesthetics while facilitating quick disassembly. Data from a certain mass-produced vehicle model shows that this design reduces assembly hours by 40%, improves maintenance efficiency by 50%, and significantly reduces after-sales costs.