How do car lights molds achieve precise reproduction of complex curves and delicate light-guiding structures?

Release Time : 2025-10-23

In modern automotive design, headlights have long transcended simple illumination to become a core vehicle for brand identity, technological expression, and aesthetic expression. From sleek, through-the-lens taillights to sharp matrix headlights, from dynamic water effects to intelligent interactive lighting, every beam of light and every curve embodies the designer's ingenuity and the brand's personality. The realization of all this is inseparable from the sophisticated and complex mold system behind it. As the "mother" of injection molding, the machining accuracy of the car lights mold directly determines the optical performance and appearance quality of the final lamp. Faced with increasingly complex curved surfaces and micron-level light-guiding structures, modern mold processing technology is achieving the highest level of craftsmanship, achieving a perfect transition from design to finished product.

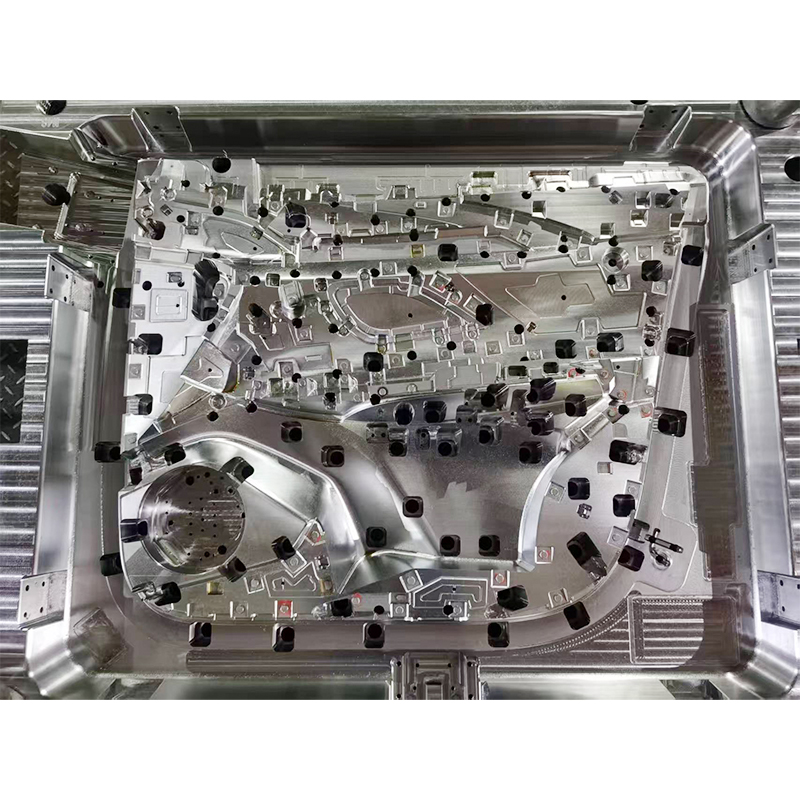

Modern headlight shades and light guides often feature free-form surfaces, characterized by smooth and asymmetrical lines, placing extremely high demands on the mold cavity's geometric reproduction capabilities. Traditional machining methods struggle to cope with these irregular shapes, but the now-widespread adoption of five-axis CNC machining technology has overcome this limitation. By continuously cutting at multiple angles, the tool can penetrate deep into complex structures, precisely carving out every undulation and turn envisioned by the designer. Whether deep cavities or narrow transition zones, machining is seamless, ensuring the mold surface is highly consistent with the 3D digital model. This "what you see is what you get" manufacturing capability enables futuristic lighting designs to move from the drawing board to reality.

A further challenge lies in replicating the light-guiding structure. The light guide strips or reflector bowls in headlights often contain dense arrays of microprisms, light-guiding dots, or textures. These structures are extremely small and require extreme precision to control the refraction, reflection, and uniform distribution of light. Deviations in the depth or angle of any particular dot can result in bright spots, dark areas, or light crosstalk. To achieve this microscopically precise replication, mold processing utilizes ultra-precision mirror-finished EDM or micro-milling processes, combined with high-magnification optical inspection equipment for real-time verification. Some high-end molds even undergo a nano-level polishing process after processing to ensure the surface is free of scratches and burrs, which would otherwise affect the light path during the injection molding process.

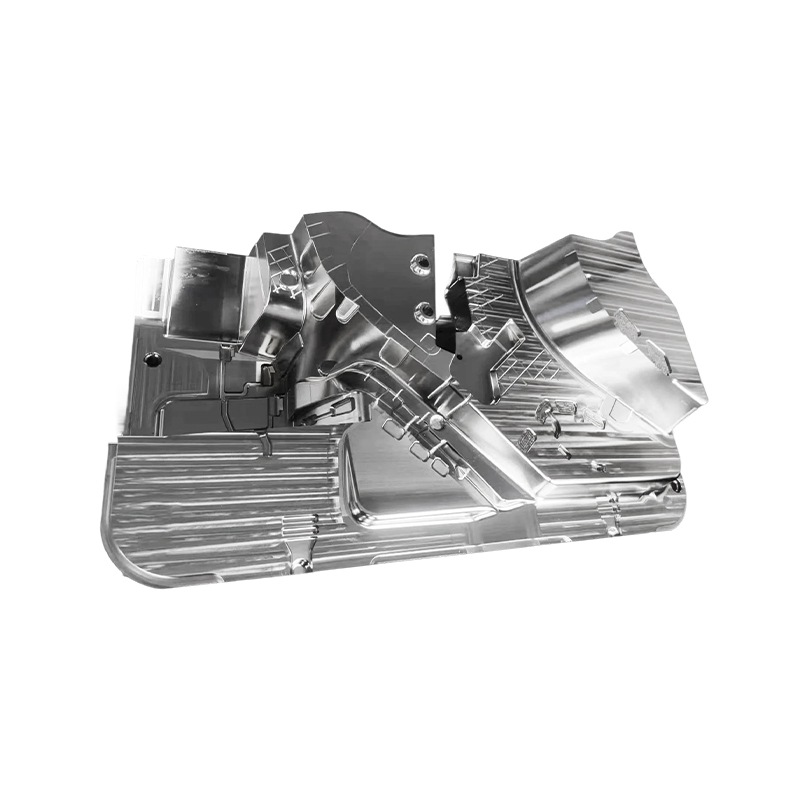

Material selection and processing are also crucial. Molds are typically constructed from high-purity, low-deformation, high-quality mold steel, undergoing multiple heat treatment steps to enhance hardness and dimensional stability. During long injection molding cycles, molds must withstand the repeated impact of high-temperature molten plastic. Inadequate material properties can easily lead to thermal fatigue cracking or surface wear, resulting in reduced product consistency. The expertly processed mold base maintains pristine precision after tens of thousands of openings and closings, ensuring consistent optical properties for every batch of lampshades.

In addition, the mold's cooling system and venting design contribute to precision. Evenly distributed cooling channels ensure synchronized solidification of the plastic within the cavity, minimizing warping caused by uneven cooling. Strategically placed venting slots prevent gas entrapment, preventing localized burning or underfilling. These seemingly auxiliary systems, in fact, work together with the cavity machining to form a complete, closed-loop precision manufacturing loop.

Ultimately, the car lights mold is more than just a sculpture of metal; it is a translator of light and form. It transforms abstract design language into a physical structure suitable for mass production, ensuring that each ray of light is precisely displayed along the intended trajectory. In the silent injection molding machines, molds are replicated time and time again, safeguarding the brand's commitment to quality. It is this crucial manufacturing force hidden behind the scenes that supports the brilliant world of modern car lights.

Modern headlight shades and light guides often feature free-form surfaces, characterized by smooth and asymmetrical lines, placing extremely high demands on the mold cavity's geometric reproduction capabilities. Traditional machining methods struggle to cope with these irregular shapes, but the now-widespread adoption of five-axis CNC machining technology has overcome this limitation. By continuously cutting at multiple angles, the tool can penetrate deep into complex structures, precisely carving out every undulation and turn envisioned by the designer. Whether deep cavities or narrow transition zones, machining is seamless, ensuring the mold surface is highly consistent with the 3D digital model. This "what you see is what you get" manufacturing capability enables futuristic lighting designs to move from the drawing board to reality.

A further challenge lies in replicating the light-guiding structure. The light guide strips or reflector bowls in headlights often contain dense arrays of microprisms, light-guiding dots, or textures. These structures are extremely small and require extreme precision to control the refraction, reflection, and uniform distribution of light. Deviations in the depth or angle of any particular dot can result in bright spots, dark areas, or light crosstalk. To achieve this microscopically precise replication, mold processing utilizes ultra-precision mirror-finished EDM or micro-milling processes, combined with high-magnification optical inspection equipment for real-time verification. Some high-end molds even undergo a nano-level polishing process after processing to ensure the surface is free of scratches and burrs, which would otherwise affect the light path during the injection molding process.

Material selection and processing are also crucial. Molds are typically constructed from high-purity, low-deformation, high-quality mold steel, undergoing multiple heat treatment steps to enhance hardness and dimensional stability. During long injection molding cycles, molds must withstand the repeated impact of high-temperature molten plastic. Inadequate material properties can easily lead to thermal fatigue cracking or surface wear, resulting in reduced product consistency. The expertly processed mold base maintains pristine precision after tens of thousands of openings and closings, ensuring consistent optical properties for every batch of lampshades.

In addition, the mold's cooling system and venting design contribute to precision. Evenly distributed cooling channels ensure synchronized solidification of the plastic within the cavity, minimizing warping caused by uneven cooling. Strategically placed venting slots prevent gas entrapment, preventing localized burning or underfilling. These seemingly auxiliary systems, in fact, work together with the cavity machining to form a complete, closed-loop precision manufacturing loop.

Ultimately, the car lights mold is more than just a sculpture of metal; it is a translator of light and form. It transforms abstract design language into a physical structure suitable for mass production, ensuring that each ray of light is precisely displayed along the intended trajectory. In the silent injection molding machines, molds are replicated time and time again, safeguarding the brand's commitment to quality. It is this crucial manufacturing force hidden behind the scenes that supports the brilliant world of modern car lights.