How to Improve the Gloss and Dimensional Stability of Car Door Panels Using Plastic Molds?

Release Time : 2025-11-06

In modern automotive interior systems, car door panels are not only crucial for functional integration but also key components influencing the overall vehicle's texture and the user's tactile experience. Consumers increasingly demand high gloss, uniform texture, and long-term deformation resistance from car door panel surfaces. Achieving these properties hinges on the precise design and process control of plastic injection molds. By optimizing mold materials, temperature management, gating systems, and cooling structures, the gloss and dimensional stability of car door panels can be simultaneously improved during mass production, meeting the quality standards of high-end vehicles.

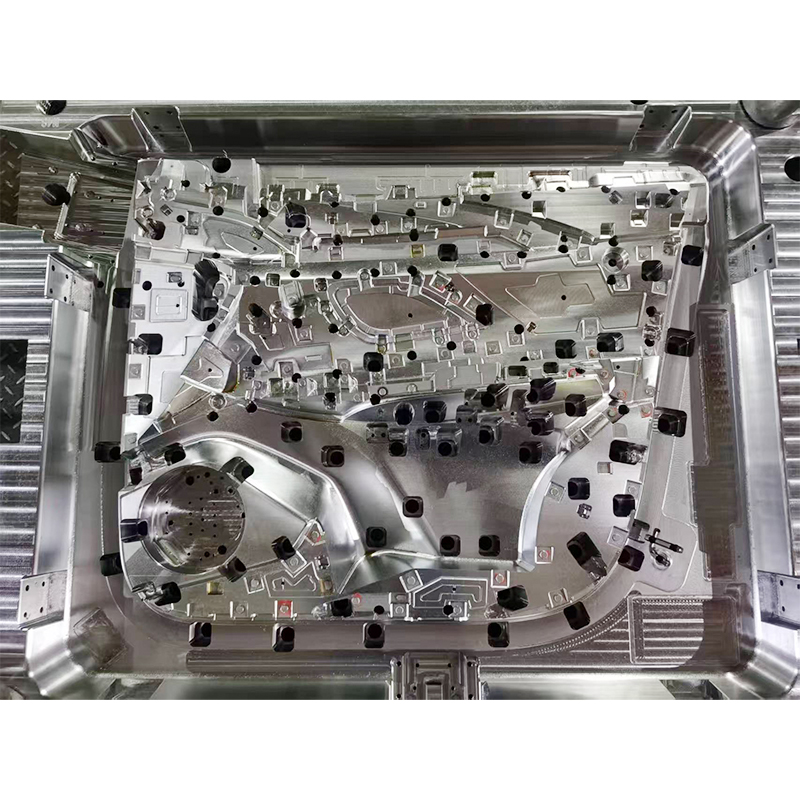

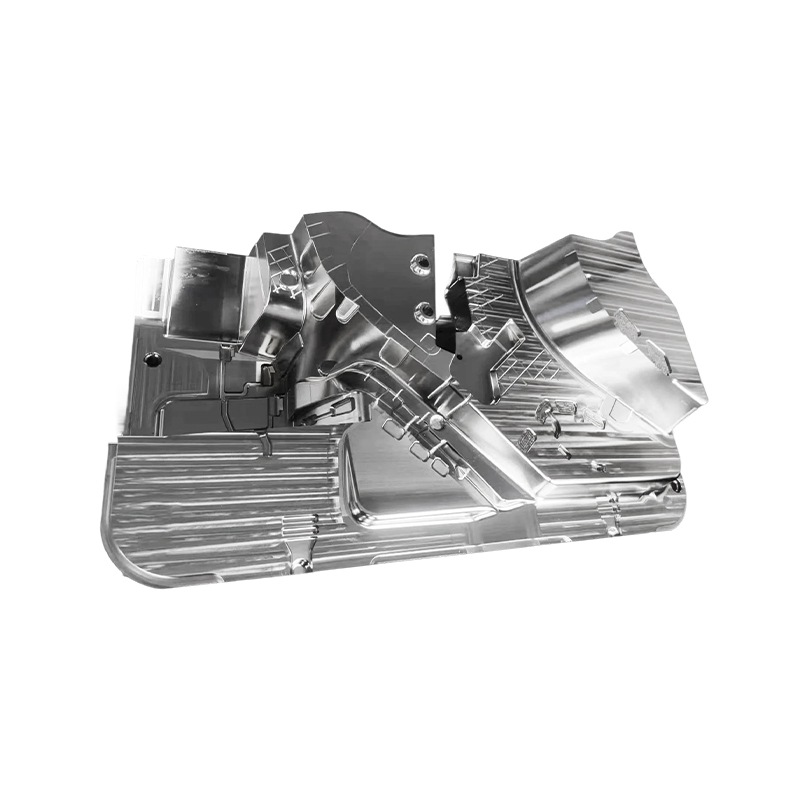

1. Mold Surface Treatment: Laying the Foundation for High Gloss

The gloss of car door panel surfaces primarily depends on the smoothness of the mold cavity. To achieve a mirror or high-gloss effect, high-purity, high-hardness pre-hardened steel is typically selected for the mold, followed by fine polishing. For paint-free high-gloss car door panels, chrome plating, nickel-phosphorus alloy, or diamond-like carbon coatings are also used, which not only improve surface hardness and wear resistance but also enhance demolding performance and prevent scratches. In addition, the mold surface must be strictly protected against rust and contamination to ensure a consistent high-gloss surface is achieved with each injection molding.

2. Precise Temperature Control System: Balancing Gloss and Internal Stress

Mold temperature is a key variable affecting gloss and dimensional stability. High mold temperatures help the melt adhere fully to the mold surface, reducing flow marks and weld lines, and improving surface finish; however, excessively high temperatures prolong cooling time and increase the risk of warpage. Therefore, modern car door panel molds generally employ zoned independent temperature control technology: the surface area maintains a higher and more uniform temperature to ensure gloss, while the structural ribs or non-surface areas are appropriately cooled to accelerate curing. Simultaneously, a closed-loop feedback system using a mold temperature controller and thermocouples controls the temperature difference within ±2℃, avoiding shrinkage differences and deformation caused by uneven cooling.

3. Optimized Gating and Cooling System: Ensuring Dimensional Accuracy

Dimensional stability is primarily determined by the shrinkage behavior of the plastic during cooling. Car door panels often use materials such as PP, ABS, or PC/ABS, each with varying shrinkage rates. Mold design requires CAE mold flow analysis to predict shrinkage trends in advance and to perform "reverse deformation compensation" during mold processing—that is, to pre-set a small reverse curvature in areas prone to warping. The gate should be located in thick-walled or non-visual areas, using a submarine gate or hot runner needle valve gate to ensure smooth melt filling and reduce orientation stress. Cooling channels should be densely arranged along the product contour, especially in thick areas such as reinforcing ribs and clips, adding conformal cooling channels to achieve uniform heat dissipation and control the overall deformation within ±0.3mm.

4. Material and Process Synergy: Maximizing Performance

While the mold is the core component, it needs to be deeply synergistic with material properties and injection molding processes. For example, high-flow PC/ABS is more suitable for molding complex car door panels, but requires higher mold venting capabilities; while PP with added talc has good rigidity, it is prone to fiber shedding, affecting gloss. Therefore, the mold design needs to reserve efficient venting grooves and install vacuum venting devices at the parting surface and ejector pins to prevent surface defects caused by trapped air. Meanwhile, injection parameters must match the mold response to avoid ejection deformation or residual internal stress.

Improving the gloss and dimensional stability of car door panels is not a simple optimization of a single step, but a systematic engineering project involving mold design, materials science, and process control. From mirror polishing to intelligent temperature control, from conformal cooling to CAE-driven structural compensation, every detail embodies the wisdom of precision manufacturing. When a car door panel is perfectly formed in the mold, behind its shimmering luster lies a millimeter-level adherence to dimensions; beneath its smooth curves lies the culmination of countless simulations and verifications. It is this dedication to "invisible precision" that makes every door opening a silent declaration of quality.

1. Mold Surface Treatment: Laying the Foundation for High Gloss

The gloss of car door panel surfaces primarily depends on the smoothness of the mold cavity. To achieve a mirror or high-gloss effect, high-purity, high-hardness pre-hardened steel is typically selected for the mold, followed by fine polishing. For paint-free high-gloss car door panels, chrome plating, nickel-phosphorus alloy, or diamond-like carbon coatings are also used, which not only improve surface hardness and wear resistance but also enhance demolding performance and prevent scratches. In addition, the mold surface must be strictly protected against rust and contamination to ensure a consistent high-gloss surface is achieved with each injection molding.

2. Precise Temperature Control System: Balancing Gloss and Internal Stress

Mold temperature is a key variable affecting gloss and dimensional stability. High mold temperatures help the melt adhere fully to the mold surface, reducing flow marks and weld lines, and improving surface finish; however, excessively high temperatures prolong cooling time and increase the risk of warpage. Therefore, modern car door panel molds generally employ zoned independent temperature control technology: the surface area maintains a higher and more uniform temperature to ensure gloss, while the structural ribs or non-surface areas are appropriately cooled to accelerate curing. Simultaneously, a closed-loop feedback system using a mold temperature controller and thermocouples controls the temperature difference within ±2℃, avoiding shrinkage differences and deformation caused by uneven cooling.

3. Optimized Gating and Cooling System: Ensuring Dimensional Accuracy

Dimensional stability is primarily determined by the shrinkage behavior of the plastic during cooling. Car door panels often use materials such as PP, ABS, or PC/ABS, each with varying shrinkage rates. Mold design requires CAE mold flow analysis to predict shrinkage trends in advance and to perform "reverse deformation compensation" during mold processing—that is, to pre-set a small reverse curvature in areas prone to warping. The gate should be located in thick-walled or non-visual areas, using a submarine gate or hot runner needle valve gate to ensure smooth melt filling and reduce orientation stress. Cooling channels should be densely arranged along the product contour, especially in thick areas such as reinforcing ribs and clips, adding conformal cooling channels to achieve uniform heat dissipation and control the overall deformation within ±0.3mm.

4. Material and Process Synergy: Maximizing Performance

While the mold is the core component, it needs to be deeply synergistic with material properties and injection molding processes. For example, high-flow PC/ABS is more suitable for molding complex car door panels, but requires higher mold venting capabilities; while PP with added talc has good rigidity, it is prone to fiber shedding, affecting gloss. Therefore, the mold design needs to reserve efficient venting grooves and install vacuum venting devices at the parting surface and ejector pins to prevent surface defects caused by trapped air. Meanwhile, injection parameters must match the mold response to avoid ejection deformation or residual internal stress.

Improving the gloss and dimensional stability of car door panels is not a simple optimization of a single step, but a systematic engineering project involving mold design, materials science, and process control. From mirror polishing to intelligent temperature control, from conformal cooling to CAE-driven structural compensation, every detail embodies the wisdom of precision manufacturing. When a car door panel is perfectly formed in the mold, behind its shimmering luster lies a millimeter-level adherence to dimensions; beneath its smooth curves lies the culmination of countless simulations and verifications. It is this dedication to "invisible precision" that makes every door opening a silent declaration of quality.