How can the injection molding of instrument panel molds achieve a seamless integration of function and aesthetics?

Release Time : 2025-11-20

In modern automotive interiors, the dashboard is not only the core carrier of information display and control, but also the first point of contact for users to perceive the overall quality of the vehicle. It must integrate complex functional modules such as air conditioning vents, airbags, displays, and wiring harness interfaces, while also presenting exquisite aesthetic effects such as high gloss, matte finish, texture, and stitching. The realization of all this highly depends on the precision machining technology of injection molding instrument panel molds. Instrument panel molds represent a perfect convergence of functional rationality and design sensibility at the millimeter level of precision.

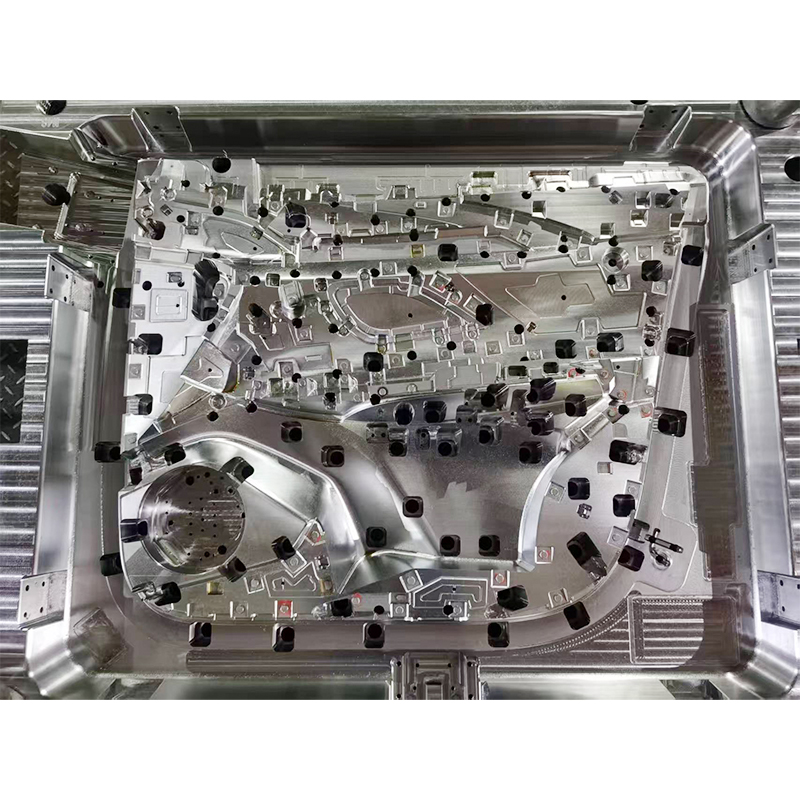

1. Structural Integration: The "Invisible Skeleton" of Functional Layout

An instrument panel mold is first and foremost a highly complex engineering system. To meet the needs of vehicle safety and human-machine interaction, the mold must precisely reserve dozens of functional features within the cavity, such as airbag burst lines, speaker openings, USB interface slots, and storage compartment latches. These structures are often nested and space-constrained, placing extremely high demands on the layout of the mold's sliders, ejector pins, and inserts. For example, the passenger-side airbag area requires an ultra-thin wall thickness and a pre-designed weakening line to ensure instantaneous deployment along a predetermined trajectory without obstruction during a collision. This necessitates high-precision EDM or laser cutting of the mold in this area, with an error controlled within ±0.05mm. Simultaneously, all functional opening edges must be smooth and burr-free to avoid scratching wiring harnesses or affecting sealing during assembly.

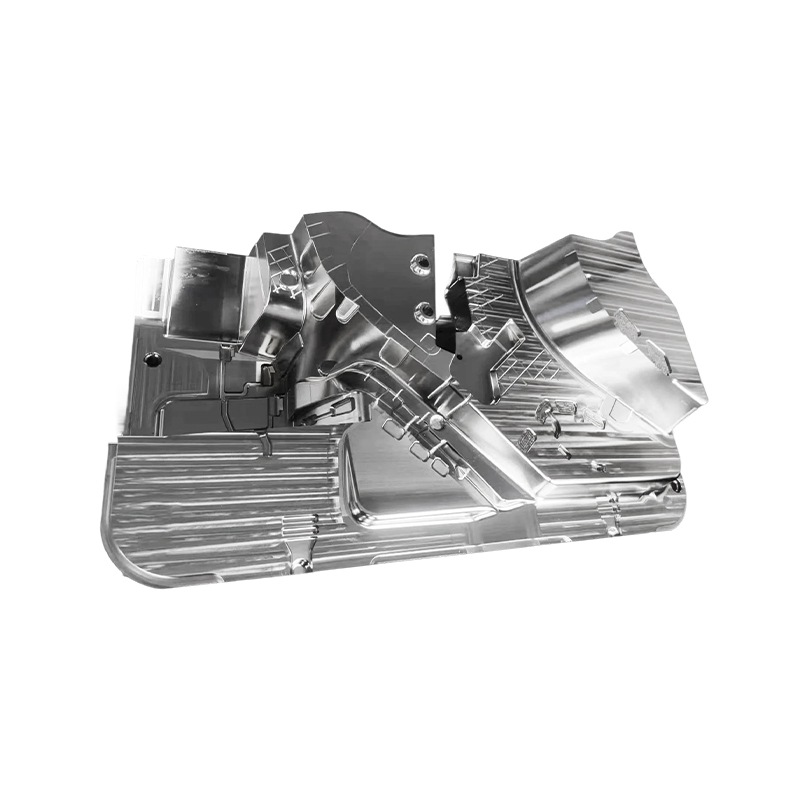

2. Surface Finishing: Exquisite Craftsmanship for Aesthetic Expression

If the functional structure is the skeleton, then the surface texture is the "skin" of the dashboard. High-end models often employ processes such as paint-free high-gloss, IMD, leather-textured textures, and laser-etched stitching, all relying on the ultimate surface treatment of the mold. Taking a high-gloss paint-free dashboard as an example, the mold cavity must be mirror-polished to Ra≤0.01μm, and a high-temperature mold temperature controller must be used to eliminate weld lines and flow marks, achieving a piano-lacquer-like gloss effect. Leather-textured treatments, on the other hand, use chemical etching or laser engraving to replicate hundreds of standard textures on the mold surface, giving the plastic part a luxurious material appearance in a single molding process. More advanced is the integration of microstructure arrays into some molds, enabling the coexistence of matte and glossy areas without post-coating, thus being both environmentally friendly and enhancing the overall texture.

3. Material and Process Synergy: Balancing Lightweight Design and Low VOCs

To comply with environmental regulations, modern dashboards often utilize low-odor, low-VOC modified PP, PC/ABS, or bio-based materials. These materials differ from traditional plastics in flowability and shrinkage rate, requiring mold design to use CAE mold flow analysis to predict warpage and shrinkage risks in advance, and optimize gate location and cooling channel layout. Conformal cooling technology is employed, utilizing 3D-printed metal inserts to construct cooling channels that conform to the product's contours, resulting in more uniform temperature distribution and significantly reducing surface defects caused by uneven cooling. This not only ensures consistent appearance but also improves dimensional stability, ensuring seamless assembly with components such as the central control screen and door panels.

4. Smart Manufacturing: A Precise Closed Loop from Virtual to Reality

The development of instrument panel molds has been fully digitized. From importing customer CAS data, DFM analysis, and 3D structural design to mold flow simulation, CNC programming, and online inspection, the entire process relies on a PLM system for collaboration. During the trial molding stage, AI visual inspection automatically identifies defects such as flash, shrinkage, and weld lines, feeding this information back to the mold correction stage. This transforms traditional "trial-and-error development" into "first-time success" precision manufacturing.

The processing of injection-molded instrument panel molds has long transcended the realm of simple metal cutting, becoming a comprehensive art integrating mechanical engineering, materials science, industrial design, and digital manufacturing. It sculpts light and shadow within steel, and carries safety within precision, ultimately transforming cold plastic into a cockpit core that combines functional reliability and emotional resonance. It is this relentless pursuit of "seamless integration" that drives automotive interiors to continuously advance towards higher dimensions of user experience.

1. Structural Integration: The "Invisible Skeleton" of Functional Layout

An instrument panel mold is first and foremost a highly complex engineering system. To meet the needs of vehicle safety and human-machine interaction, the mold must precisely reserve dozens of functional features within the cavity, such as airbag burst lines, speaker openings, USB interface slots, and storage compartment latches. These structures are often nested and space-constrained, placing extremely high demands on the layout of the mold's sliders, ejector pins, and inserts. For example, the passenger-side airbag area requires an ultra-thin wall thickness and a pre-designed weakening line to ensure instantaneous deployment along a predetermined trajectory without obstruction during a collision. This necessitates high-precision EDM or laser cutting of the mold in this area, with an error controlled within ±0.05mm. Simultaneously, all functional opening edges must be smooth and burr-free to avoid scratching wiring harnesses or affecting sealing during assembly.

2. Surface Finishing: Exquisite Craftsmanship for Aesthetic Expression

If the functional structure is the skeleton, then the surface texture is the "skin" of the dashboard. High-end models often employ processes such as paint-free high-gloss, IMD, leather-textured textures, and laser-etched stitching, all relying on the ultimate surface treatment of the mold. Taking a high-gloss paint-free dashboard as an example, the mold cavity must be mirror-polished to Ra≤0.01μm, and a high-temperature mold temperature controller must be used to eliminate weld lines and flow marks, achieving a piano-lacquer-like gloss effect. Leather-textured treatments, on the other hand, use chemical etching or laser engraving to replicate hundreds of standard textures on the mold surface, giving the plastic part a luxurious material appearance in a single molding process. More advanced is the integration of microstructure arrays into some molds, enabling the coexistence of matte and glossy areas without post-coating, thus being both environmentally friendly and enhancing the overall texture.

3. Material and Process Synergy: Balancing Lightweight Design and Low VOCs

To comply with environmental regulations, modern dashboards often utilize low-odor, low-VOC modified PP, PC/ABS, or bio-based materials. These materials differ from traditional plastics in flowability and shrinkage rate, requiring mold design to use CAE mold flow analysis to predict warpage and shrinkage risks in advance, and optimize gate location and cooling channel layout. Conformal cooling technology is employed, utilizing 3D-printed metal inserts to construct cooling channels that conform to the product's contours, resulting in more uniform temperature distribution and significantly reducing surface defects caused by uneven cooling. This not only ensures consistent appearance but also improves dimensional stability, ensuring seamless assembly with components such as the central control screen and door panels.

4. Smart Manufacturing: A Precise Closed Loop from Virtual to Reality

The development of instrument panel molds has been fully digitized. From importing customer CAS data, DFM analysis, and 3D structural design to mold flow simulation, CNC programming, and online inspection, the entire process relies on a PLM system for collaboration. During the trial molding stage, AI visual inspection automatically identifies defects such as flash, shrinkage, and weld lines, feeding this information back to the mold correction stage. This transforms traditional "trial-and-error development" into "first-time success" precision manufacturing.

The processing of injection-molded instrument panel molds has long transcended the realm of simple metal cutting, becoming a comprehensive art integrating mechanical engineering, materials science, industrial design, and digital manufacturing. It sculpts light and shadow within steel, and carries safety within precision, ultimately transforming cold plastic into a cockpit core that combines functional reliability and emotional resonance. It is this relentless pursuit of "seamless integration" that drives automotive interiors to continuously advance towards higher dimensions of user experience.