How Does Die Casting Mold Machining Unlock the Secrets of Complex Casting Forming?

Release Time : 2025-12-04

Die casting molds are the ultimate guarantee of product precision, surface quality, and production efficiency. The crucial step in transforming design drawings into high-performance molds—die casting mold machining—is continuously unlocking the secrets of complex casting forming with micron-level precision.

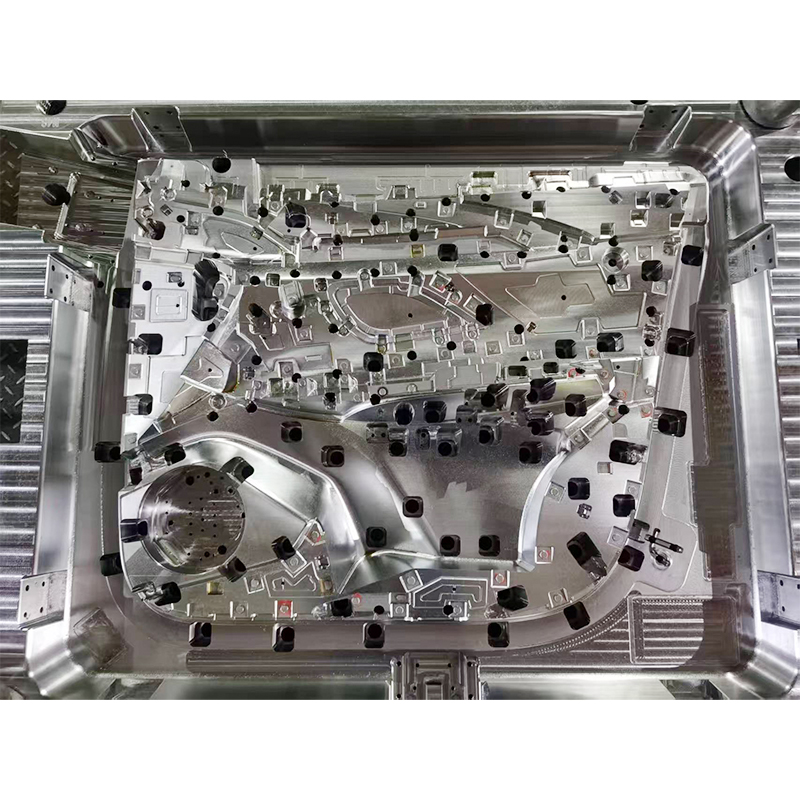

1. From Billet to Cavity: A Precision Symphony of Multi-Process Collaboration

Die casting molds typically consist of hundreds of precision components, including the mold core, slide block, ejector pins, cooling system, and venting structure. Their machining is not a single-step process but rather a precise collaboration of multiple processes such as high-speed milling, electrical discharge machining (EDM), deep hole drilling, wire cutting, and mirror polishing. For example, the main cavity is achieved through efficient roughing and finishing using five-axis high-speed milling, ensuring the accuracy of complex curved surface contours; while fine ribs, deep grooves, or undercut structures are completed using slow wire cutting or precision EDM, achieving dimensional control of ±0.002mm. This "rigid-flexible" machining strategy ensures both efficiency and overcomes detailed challenges.

2. Materials and Heat Treatment: The Cornerstone of Performance

Die casting molds commonly use H13 hot work die steel, requiring rigorous quenching and multiple tempering processes to achieve high hardness, excellent resistance to thermal fatigue, and good thermal conductivity. However, the heat treatment process can easily induce deformation, and improper control of subsequent machining allowances can lead to out-of-tolerance issues on critical mating surfaces. Therefore, advanced companies generally adopt a process of pre-hardened steel rough machining → heat treatment → finish machining, combined with finite element simulation to predict deformation trends and compensate for machining paths in advance, ensuring final assembly accuracy.

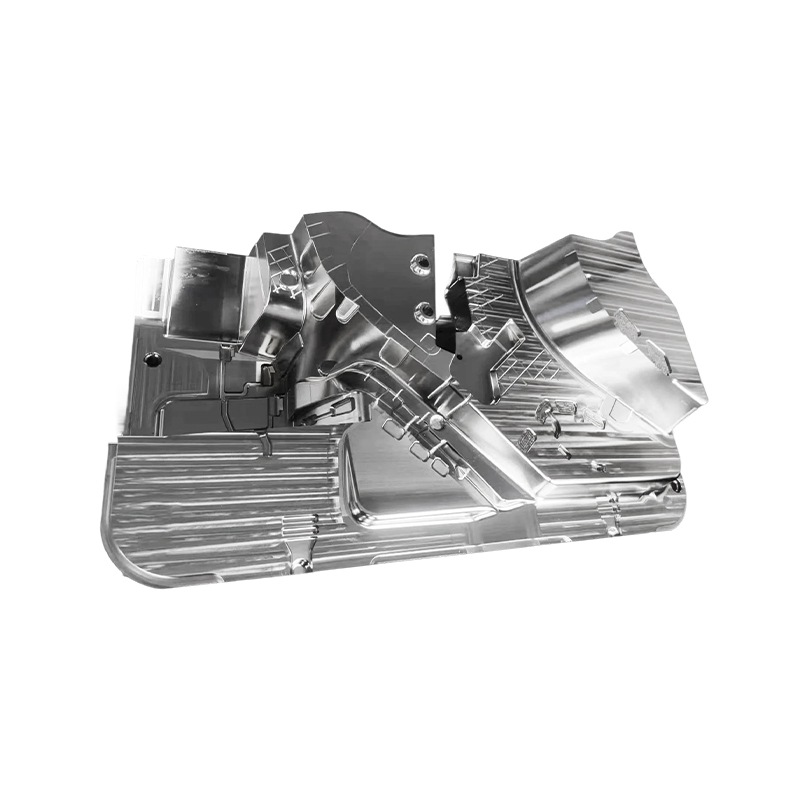

3. Conformal Cooling and Microstructure: Key to Improving Casting Quality

Modern die casting demands extremely high internal density and surface finish in castings. Therefore, mold processing requires the precise manufacture of conformal cooling channels—these channels closely follow the cavity contour, achieved through additive manufacturing or deep hole drilling with plugging processes, significantly improving heat dissipation uniformity and reducing shrinkage cavities and deformation. Meanwhile, the depth of the exhaust groove is often controlled within 0.02–0.04 mm, and the position and shape of the overflow well must match the metal flow pattern. If these microstructures are poorly machined or have dimensional deviations, they are highly susceptible to defects such as porosity and cold shuts. High-precision machining is key to solving these "invisible killers."

4. Intelligentization and Digitalization: Driving a Leap in Efficiency

With the advancement of Industry 4.0, die casting mold processing is moving towards intelligentization. CAM software automatically identifies features and generates optimal toolpaths, reducing manual programming errors; on-machine measurement systems provide real-time feedback on dimensional deviations and automatically compensate for subsequent processes; digital twin platforms link design, machining, and trial molding data in a closed loop, achieving "doing it right the first time." A new energy vehicle company's integrated rear base plate die casting mold, through full-process digital management, has shortened the processing cycle by 35% and reduced the number of trial moldings by 50%.

Die casting mold processing is a dialogue between metal and intelligence, a contest between millimeters and micrometers. Behind every successful mold lies the ultimate fusion of materials, processes, precision, and experience. In the journey of "Made in China" to "Precision Manufacturing in China", it is these machine tools that operate silently in the workshop and the code in the hands of craftsmen that, with the power of precision carving, continue to unlock the molding code of high-end manufacturing.

1. From Billet to Cavity: A Precision Symphony of Multi-Process Collaboration

Die casting molds typically consist of hundreds of precision components, including the mold core, slide block, ejector pins, cooling system, and venting structure. Their machining is not a single-step process but rather a precise collaboration of multiple processes such as high-speed milling, electrical discharge machining (EDM), deep hole drilling, wire cutting, and mirror polishing. For example, the main cavity is achieved through efficient roughing and finishing using five-axis high-speed milling, ensuring the accuracy of complex curved surface contours; while fine ribs, deep grooves, or undercut structures are completed using slow wire cutting or precision EDM, achieving dimensional control of ±0.002mm. This "rigid-flexible" machining strategy ensures both efficiency and overcomes detailed challenges.

2. Materials and Heat Treatment: The Cornerstone of Performance

Die casting molds commonly use H13 hot work die steel, requiring rigorous quenching and multiple tempering processes to achieve high hardness, excellent resistance to thermal fatigue, and good thermal conductivity. However, the heat treatment process can easily induce deformation, and improper control of subsequent machining allowances can lead to out-of-tolerance issues on critical mating surfaces. Therefore, advanced companies generally adopt a process of pre-hardened steel rough machining → heat treatment → finish machining, combined with finite element simulation to predict deformation trends and compensate for machining paths in advance, ensuring final assembly accuracy.

3. Conformal Cooling and Microstructure: Key to Improving Casting Quality

Modern die casting demands extremely high internal density and surface finish in castings. Therefore, mold processing requires the precise manufacture of conformal cooling channels—these channels closely follow the cavity contour, achieved through additive manufacturing or deep hole drilling with plugging processes, significantly improving heat dissipation uniformity and reducing shrinkage cavities and deformation. Meanwhile, the depth of the exhaust groove is often controlled within 0.02–0.04 mm, and the position and shape of the overflow well must match the metal flow pattern. If these microstructures are poorly machined or have dimensional deviations, they are highly susceptible to defects such as porosity and cold shuts. High-precision machining is key to solving these "invisible killers."

4. Intelligentization and Digitalization: Driving a Leap in Efficiency

With the advancement of Industry 4.0, die casting mold processing is moving towards intelligentization. CAM software automatically identifies features and generates optimal toolpaths, reducing manual programming errors; on-machine measurement systems provide real-time feedback on dimensional deviations and automatically compensate for subsequent processes; digital twin platforms link design, machining, and trial molding data in a closed loop, achieving "doing it right the first time." A new energy vehicle company's integrated rear base plate die casting mold, through full-process digital management, has shortened the processing cycle by 35% and reduced the number of trial moldings by 50%.

Die casting mold processing is a dialogue between metal and intelligence, a contest between millimeters and micrometers. Behind every successful mold lies the ultimate fusion of materials, processes, precision, and experience. In the journey of "Made in China" to "Precision Manufacturing in China", it is these machine tools that operate silently in the workshop and the code in the hands of craftsmen that, with the power of precision carving, continue to unlock the molding code of high-end manufacturing.