How to control the thermal deformation of welded inserts in automotive instrument panel mold manufacturing through process compensation?

Release Time : 2025-12-19

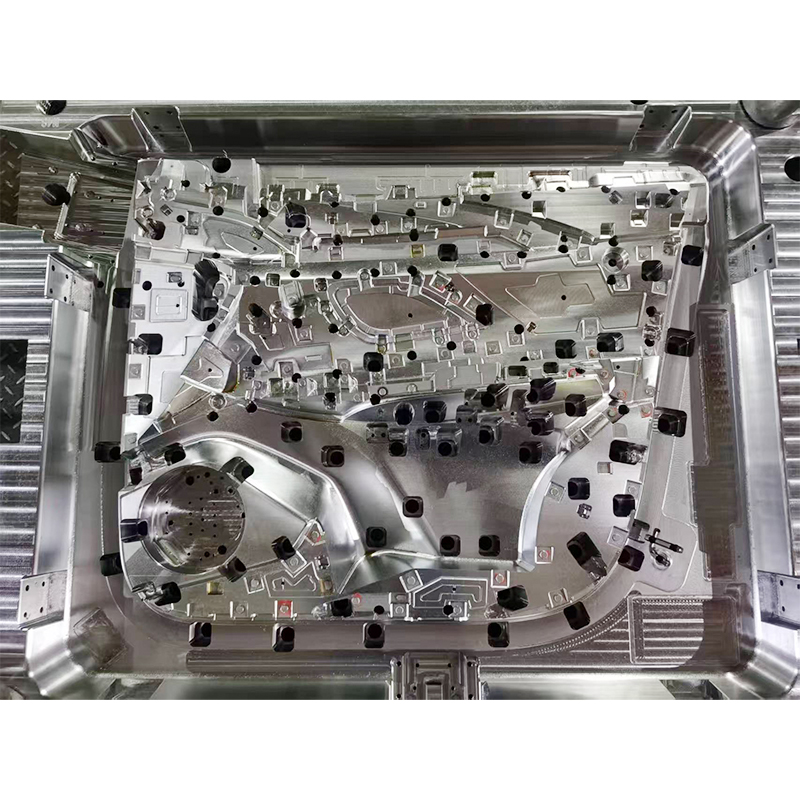

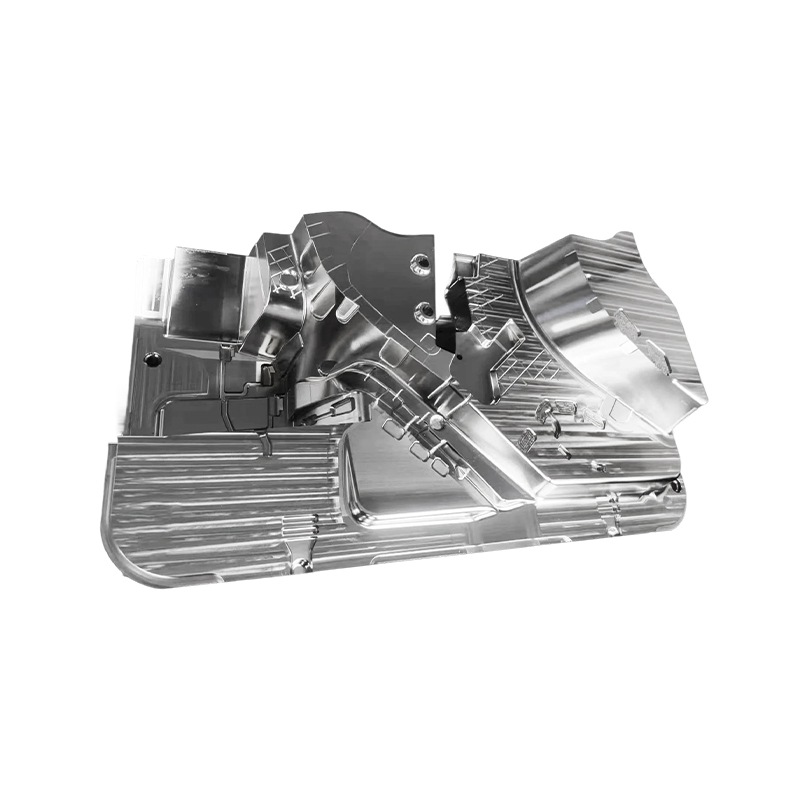

In automotive instrument panel mold manufacturing, large and complex structures often require welded inserts to balance strength, cost, and processing feasibility. However, the welding process inevitably introduces localized high temperatures, leading to uneven thermal expansion and contraction of the material, resulting in residual stress and geometric deformation. If not controlled, this directly affects mold closing accuracy, product dimensional stability, and even the injection molding appearance quality. Therefore, process compensation technology has become a key aspect of high-precision instrument panel mold manufacturing. Through a three-pronged strategy of "prediction-simulation-correction," the thermal deformation of welded inserts is effectively suppressed, ensuring that the final assembly and molding performance meets standards.

1. Welding Deformation Mechanism: The Dual Effect of Thermal Stress and Microstructure Changes

During welding, the weld area instantly heats up above its melting point, while the surrounding base material remains at a lower temperature, creating a severe temperature gradient. During cooling, the high-temperature zone experiences hindered contraction, generating tensile stress; simultaneously, the metal phase transformation further exacerbates the volume change. For large P20 or H13 steel instrument panel mold inserts, this uneven shrinkage often leads to planar warping, hole misalignment, or contour distortion, with deviations reaching 0.1–0.5 mm, far exceeding the mold industry's ±0.02 mm assembly tolerance requirement.

2. CAE Thermo-Mechanical Coupled Simulation: Deformation Prediction

Modern mold factories introduce finite element analysis software before welding to create a 3D model of the insert and set material properties, welding parameters, fixture constraints, and other boundary conditions. Through thermo-mechanical coupled simulation, the deformation trend and maximum displacement area after welding are accurately predicted. For example, simulation of a dashboard central air vent insert shows that the top edge will warp upwards by 0.32 mm, and the locating pin holes on both sides will shrink inwards by 0.18 mm. This data becomes the "digital blueprint" for subsequent process compensation.

3. Reverse Pre-deformation Compensation: Making the Mold "Bend First, Straighten Later"

Based on simulation results, engineers perform reverse pre-deformation on the original blank of the insert during the CNC machining stage—that is, reserving "overcutting allowance" in the opposite direction of the expected deformation. For example, if a 0.3mm upward arch is predicted after welding, a 0.3mm concave surface is pre-machined during milling of the top surface; if the hole will shrink, the drilling diameter is slightly larger or the location is expanded outwards. After welding, thermal deformation precisely offsets the preset deformation, allowing the final geometry to return to the design baseline. This method requires extremely high modeling accuracy and process experience, but it can approximate the target morphology in one go, significantly reducing trial-and-error costs.

4. Optimize Welding Process and Post-processing: Suppress Deformation from the Source

In addition to geometric compensation, the process itself also requires meticulous control:

Use low-heat-input welding technology to reduce the heat-affected zone; use segmented skip welding or symmetrical welding sequences to balance heat accumulation; use rigid fixtures and in-weld cooling to restrict free deformation; use post-weld stress-relief annealing to release residual stress. These measures, in conjunction with process compensation, form a double insurance of "prevention + correction".

5. Closed-Loop Verification and Data Accumulation: Building an Enterprise Knowledge Base

After the first prototype is manufactured, actual deformation data is obtained through coordinate measuring machine or optical scanning, compared with simulation, and the model parameters are calibrated. A long-term accumulated database of "materials-processes-deformation" allows for direct access to compensation schemes for similar inserts in the future, achieving a leap from "experience-driven" to "data-driven" approaches.

In the field of instrument panel mold manufacturing, which pursues zero defects and high efficiency, controlling the thermal deformation of welded inserts is no longer a "post-mortem remedy," but a systematic engineering process that permeates the entire process of design, simulation, processing, and welding. Through scientific process compensation strategies, mold manufacturers can not only ensure the dimensional and appearance quality of highly visible interior components such as dashboards, but also win the trust and orders of OEMs with their technological strength in the fierce global supply chain competition. Behind this lies a paradigm of deep integration between precision manufacturing and digital intelligence.

1. Welding Deformation Mechanism: The Dual Effect of Thermal Stress and Microstructure Changes

During welding, the weld area instantly heats up above its melting point, while the surrounding base material remains at a lower temperature, creating a severe temperature gradient. During cooling, the high-temperature zone experiences hindered contraction, generating tensile stress; simultaneously, the metal phase transformation further exacerbates the volume change. For large P20 or H13 steel instrument panel mold inserts, this uneven shrinkage often leads to planar warping, hole misalignment, or contour distortion, with deviations reaching 0.1–0.5 mm, far exceeding the mold industry's ±0.02 mm assembly tolerance requirement.

2. CAE Thermo-Mechanical Coupled Simulation: Deformation Prediction

Modern mold factories introduce finite element analysis software before welding to create a 3D model of the insert and set material properties, welding parameters, fixture constraints, and other boundary conditions. Through thermo-mechanical coupled simulation, the deformation trend and maximum displacement area after welding are accurately predicted. For example, simulation of a dashboard central air vent insert shows that the top edge will warp upwards by 0.32 mm, and the locating pin holes on both sides will shrink inwards by 0.18 mm. This data becomes the "digital blueprint" for subsequent process compensation.

3. Reverse Pre-deformation Compensation: Making the Mold "Bend First, Straighten Later"

Based on simulation results, engineers perform reverse pre-deformation on the original blank of the insert during the CNC machining stage—that is, reserving "overcutting allowance" in the opposite direction of the expected deformation. For example, if a 0.3mm upward arch is predicted after welding, a 0.3mm concave surface is pre-machined during milling of the top surface; if the hole will shrink, the drilling diameter is slightly larger or the location is expanded outwards. After welding, thermal deformation precisely offsets the preset deformation, allowing the final geometry to return to the design baseline. This method requires extremely high modeling accuracy and process experience, but it can approximate the target morphology in one go, significantly reducing trial-and-error costs.

4. Optimize Welding Process and Post-processing: Suppress Deformation from the Source

In addition to geometric compensation, the process itself also requires meticulous control:

Use low-heat-input welding technology to reduce the heat-affected zone; use segmented skip welding or symmetrical welding sequences to balance heat accumulation; use rigid fixtures and in-weld cooling to restrict free deformation; use post-weld stress-relief annealing to release residual stress. These measures, in conjunction with process compensation, form a double insurance of "prevention + correction".

5. Closed-Loop Verification and Data Accumulation: Building an Enterprise Knowledge Base

After the first prototype is manufactured, actual deformation data is obtained through coordinate measuring machine or optical scanning, compared with simulation, and the model parameters are calibrated. A long-term accumulated database of "materials-processes-deformation" allows for direct access to compensation schemes for similar inserts in the future, achieving a leap from "experience-driven" to "data-driven" approaches.

In the field of instrument panel mold manufacturing, which pursues zero defects and high efficiency, controlling the thermal deformation of welded inserts is no longer a "post-mortem remedy," but a systematic engineering process that permeates the entire process of design, simulation, processing, and welding. Through scientific process compensation strategies, mold manufacturers can not only ensure the dimensional and appearance quality of highly visible interior components such as dashboards, but also win the trust and orders of OEMs with their technological strength in the fierce global supply chain competition. Behind this lies a paradigm of deep integration between precision manufacturing and digital intelligence.