Exploring How to Optimize Heat Treatment Processes to Enhance Wear Resistance in Automotive Die Casting Mold Manufacturing?

Release Time : 2026-01-01

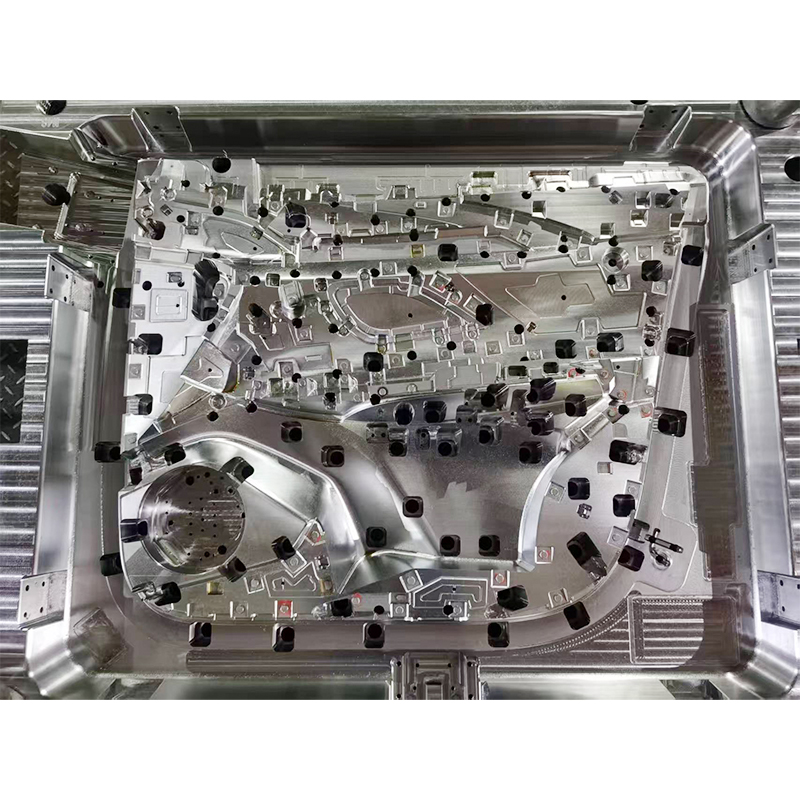

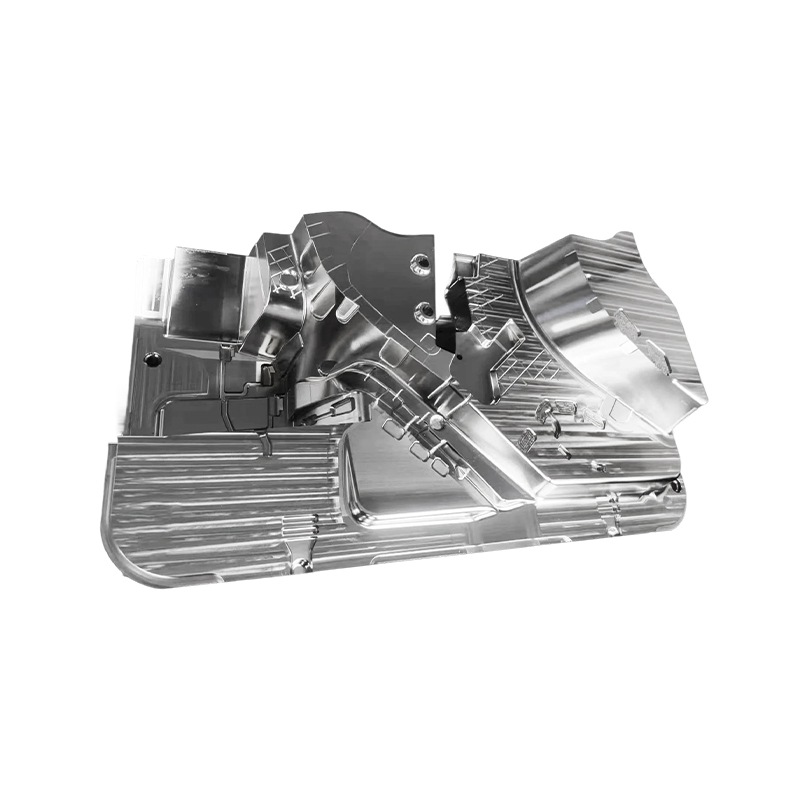

In the automotive manufacturing industry, automotive die casting molds are widely used in the production of key aluminum or magnesium alloy structural parts such as engine blocks, gearbox housings, and chassis brackets. As the core carrier of this efficient forming technology, die casting molds are subjected to long-term impacts from molten metal at temperatures as high as 600–900℃, intense thermal cycling, and high-pressure erosion, making them highly susceptible to problems such as cracking, sticking, erosion, and wear. Insufficient wear resistance is a major cause of shortened mold life, decreased casting surface quality, and even downtime for maintenance. To address this challenge, precise optimization of the heat treatment process has become a key breakthrough in improving mold performance—it not only determines the balance between the material's hardness and toughness but also directly affects the stability of the microstructure and fatigue resistance.

1. Material Basis and Heat Treatment Objectives

Automotive die casting molds mostly use high-quality hot-work die steels, whose core alloying elements endow the material with high-temperature strength and resistance to tempering softening. The core objective of heat treatment is to achieve high hardness to resist wear while retaining sufficient toughness to inhibit thermal fatigue crack propagation, and ensuring uniform microstructure and minimal residual stress. Traditional processes include quenching followed by multiple high-temperature tempering processes. However, improper parameter control can easily lead to carbide coarsening, grain boundary weakening, or temper brittleness, thus accelerating failure.

2. Staged Quenching and Isothermal Quenching: Suppressing Deformation and Cracking

To reduce deformation or cracking caused by thermal and microstructural stresses during quenching, high-end molds commonly employ staged quenching or isothermal quenching. The former involves briefly immersing the mold in a salt bath slightly above the Ms point to achieve uniform cross-sectional temperature before air cooling, significantly reducing internal stress. The latter involves holding the mold in the bainite transformation zone to obtain a lower bainite microstructure, combining high strength and high toughness. Although these two processes are more expensive, they significantly improve the dimensional stability of the mold, laying the foundation for subsequent precision machining and long-term service.

3. Cryogenic Treatment: Enhancing Microstructure Integrity and Wear Resistance

Introducing cryogenic treatment after quenching promotes the further transformation of retained austenite into martensite, increasing hardness by 2–4 HRC and refining carbide distribution. More importantly, cryogenic treatment eliminates micropores, closes microcracks, and enhances material density. Experiments show that cryogenically treated H13 mold steel exhibits over 20% improved wear resistance and significantly extended thermal fatigue life, making it particularly suitable for large automotive die-casting molds with high cycle counts.

4. Vacuum High-Pressure Gas Quenching: Ensuring Surface Cleanliness and Uniform Performance

Traditional oil quenching easily leads to oxidation, decarburization, and oil residue on the mold surface, affecting the adhesion of subsequent nitriding or PVD coatings. Modern high-end mold processing widely adopts vacuum high-pressure gas quenching technology: heating in a vacuum environment followed by high-speed cooling with high-purity nitrogen or helium. This process not only avoids surface contamination but also achieves uniform cooling of complex cavities by adjusting gas pressure and flow rate, reducing hardness gradients and ensuring consistent performance across the entire mold working surface.

5. Refined Tempering Process: Stress Relief and Microstructure Stabilization

Tempering is a crucial step determining the final performance. Three or more high-temperature tempering processes (which allow for the dispersion of alloy carbides, producing a secondary hardening effect, and simultaneously eliminating quenching stress) can prevent temper brittleness and promote the stabilization of residual austenite. Some companies have also introduced stress monitoring systems during the tempering process to adjust the process curve in real time, ensuring that the residual stress inside the mold remains below the safe threshold.

6. Synergistic Effect with Surface Strengthening Technology

Heat treatment provides the mold with "internal strength," while subsequent surface treatment builds "external armor." However, if the substrate hardness is insufficient or defects exist, the coating is prone to peeling. Therefore, optimized heat treatment must provide ideal support for surface engineering—a clean surface with high hardness, low roughness, and no decarburized layer—to achieve the optimal combination of "core toughness and surface hardness," ensuring the mold's durable wear resistance in harsh die-casting environments.

Automotive die casting mold wear resistance of a mold is not the result of a single process, but rather a manifestation of precise control throughout the entire heat treatment chain. From material selection, heating uniformity, and cooling rate to tempering stability, each step concerns the microscopic evolution of the material. Through the integrated application of advanced techniques such as graded quenching, cryogenic treatment, vacuum quenching, and fine tempering, modern heat treatment processes are transforming molds from "consumable materials" into "long-lasting assets." In the wave of lightweighting in new energy vehicles, this invisible technological innovation is quietly supporting every efficient and stable die-casting process, driving green manufacturing towards a new era of higher precision and longer lifespan.

1. Material Basis and Heat Treatment Objectives

Automotive die casting molds mostly use high-quality hot-work die steels, whose core alloying elements endow the material with high-temperature strength and resistance to tempering softening. The core objective of heat treatment is to achieve high hardness to resist wear while retaining sufficient toughness to inhibit thermal fatigue crack propagation, and ensuring uniform microstructure and minimal residual stress. Traditional processes include quenching followed by multiple high-temperature tempering processes. However, improper parameter control can easily lead to carbide coarsening, grain boundary weakening, or temper brittleness, thus accelerating failure.

2. Staged Quenching and Isothermal Quenching: Suppressing Deformation and Cracking

To reduce deformation or cracking caused by thermal and microstructural stresses during quenching, high-end molds commonly employ staged quenching or isothermal quenching. The former involves briefly immersing the mold in a salt bath slightly above the Ms point to achieve uniform cross-sectional temperature before air cooling, significantly reducing internal stress. The latter involves holding the mold in the bainite transformation zone to obtain a lower bainite microstructure, combining high strength and high toughness. Although these two processes are more expensive, they significantly improve the dimensional stability of the mold, laying the foundation for subsequent precision machining and long-term service.

3. Cryogenic Treatment: Enhancing Microstructure Integrity and Wear Resistance

Introducing cryogenic treatment after quenching promotes the further transformation of retained austenite into martensite, increasing hardness by 2–4 HRC and refining carbide distribution. More importantly, cryogenic treatment eliminates micropores, closes microcracks, and enhances material density. Experiments show that cryogenically treated H13 mold steel exhibits over 20% improved wear resistance and significantly extended thermal fatigue life, making it particularly suitable for large automotive die-casting molds with high cycle counts.

4. Vacuum High-Pressure Gas Quenching: Ensuring Surface Cleanliness and Uniform Performance

Traditional oil quenching easily leads to oxidation, decarburization, and oil residue on the mold surface, affecting the adhesion of subsequent nitriding or PVD coatings. Modern high-end mold processing widely adopts vacuum high-pressure gas quenching technology: heating in a vacuum environment followed by high-speed cooling with high-purity nitrogen or helium. This process not only avoids surface contamination but also achieves uniform cooling of complex cavities by adjusting gas pressure and flow rate, reducing hardness gradients and ensuring consistent performance across the entire mold working surface.

5. Refined Tempering Process: Stress Relief and Microstructure Stabilization

Tempering is a crucial step determining the final performance. Three or more high-temperature tempering processes (which allow for the dispersion of alloy carbides, producing a secondary hardening effect, and simultaneously eliminating quenching stress) can prevent temper brittleness and promote the stabilization of residual austenite. Some companies have also introduced stress monitoring systems during the tempering process to adjust the process curve in real time, ensuring that the residual stress inside the mold remains below the safe threshold.

6. Synergistic Effect with Surface Strengthening Technology

Heat treatment provides the mold with "internal strength," while subsequent surface treatment builds "external armor." However, if the substrate hardness is insufficient or defects exist, the coating is prone to peeling. Therefore, optimized heat treatment must provide ideal support for surface engineering—a clean surface with high hardness, low roughness, and no decarburized layer—to achieve the optimal combination of "core toughness and surface hardness," ensuring the mold's durable wear resistance in harsh die-casting environments.

Automotive die casting mold wear resistance of a mold is not the result of a single process, but rather a manifestation of precise control throughout the entire heat treatment chain. From material selection, heating uniformity, and cooling rate to tempering stability, each step concerns the microscopic evolution of the material. Through the integrated application of advanced techniques such as graded quenching, cryogenic treatment, vacuum quenching, and fine tempering, modern heat treatment processes are transforming molds from "consumable materials" into "long-lasting assets." In the wave of lightweighting in new energy vehicles, this invisible technological innovation is quietly supporting every efficient and stable die-casting process, driving green manufacturing towards a new era of higher precision and longer lifespan.