-

2026-02-11 2026-02-11

How to balance the contradiction between cutting performance and wear resistance in the machining of car light molds using high-hardness mold steel?

The machined surface of high-hardness mold steel must simultaneously meet requirements such as low roughness, absence of microcracks, and residual compressive stress to ensure the wear resistance and fatigue resistance of the mold. -

2026-01-30 2026-01-30

How can the flexible design of plastic molds for car lights meet diverse styling needs and enhance the aesthetic appeal of vehicles?

From streamlined, continuous taillights to sharp, blade-like daytime running lights, from 3D light strips to pixelated interactive matrices, car lights are becoming increasingly complex, sophisticated, and personalized. Behind all this visual innovation l -

2026-01-15 2026-01-15

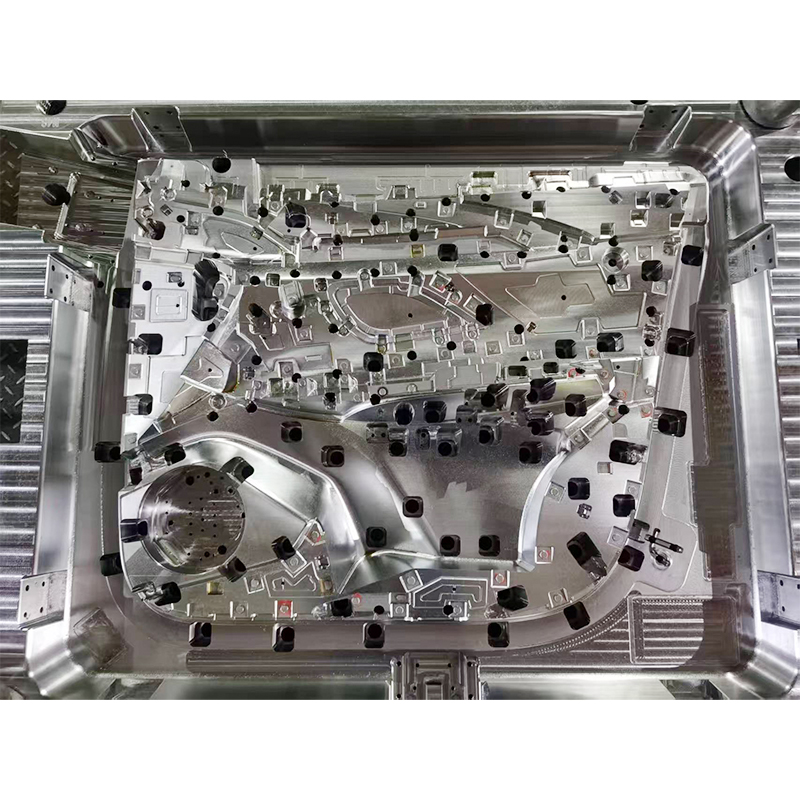

How to ensure car door panel molds maintain micron-level dimensional accuracy on large curved surfaces?

In modern automotive manufacturing, car door panels are no longer simple coverings, but rather sophisticated interior assemblies integrating aesthetics, functionality, and human-machine interaction. -

2026-01-01 2026-01-01

Exploring How to Optimize Heat Treatment Processes to Enhance Wear Resistance in Automotive Die Casting Mold Manufacturing?

In the automotive manufacturing industry, automotive die casting molds are widely used in the production of key aluminum or magnesium alloy structural parts such as engine blocks, gearbox housings, and chassis brackets. -

2025-12-19 2025-12-19

How to control the thermal deformation of welded inserts in automotive instrument panel mold manufacturing through process compensation?

In automotive instrument panel mold manufacturing, large and complex structures often require welded inserts to balance strength, cost, and processing feasibility. -

2025-12-04 2025-12-04

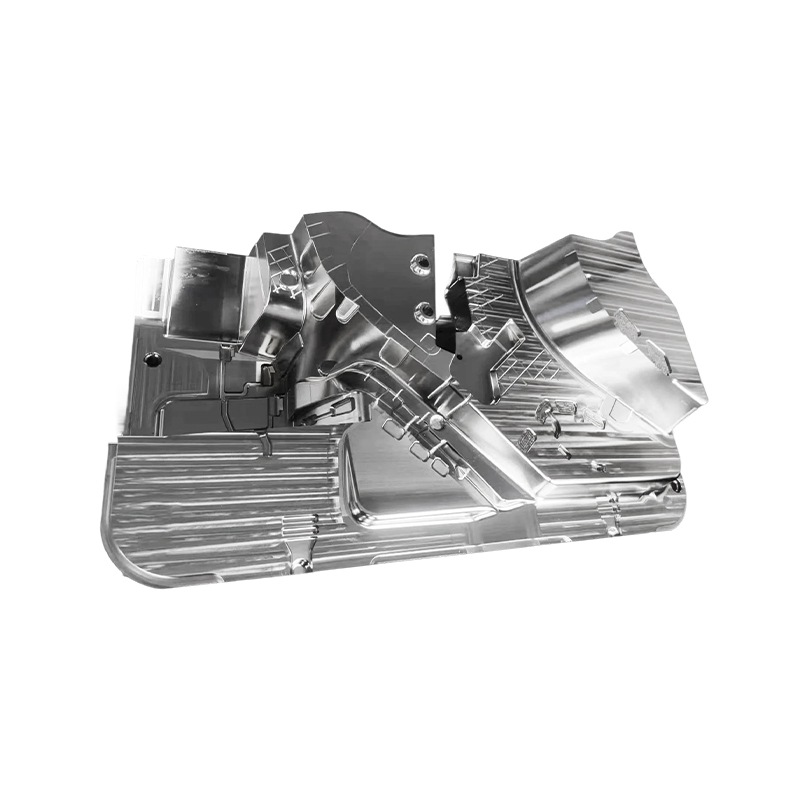

How Does Die Casting Mold Machining Unlock the Secrets of Complex Casting Forming?

Die casting molds are the ultimate guarantee of product precision, surface quality, and production efficiency. The crucial step in transforming design drawings into high-performance molds—die casting mold machining—is continuously unlocking the secrets of